Ceramic processing

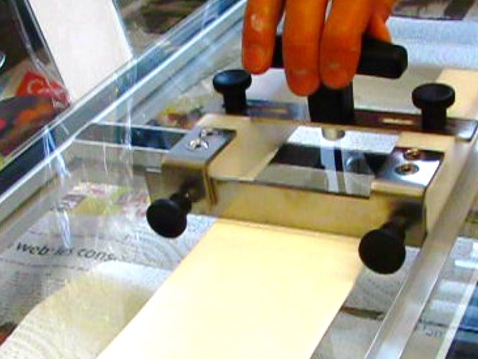

and slurries for tape casting

Organic and aqueous slurry formulation:

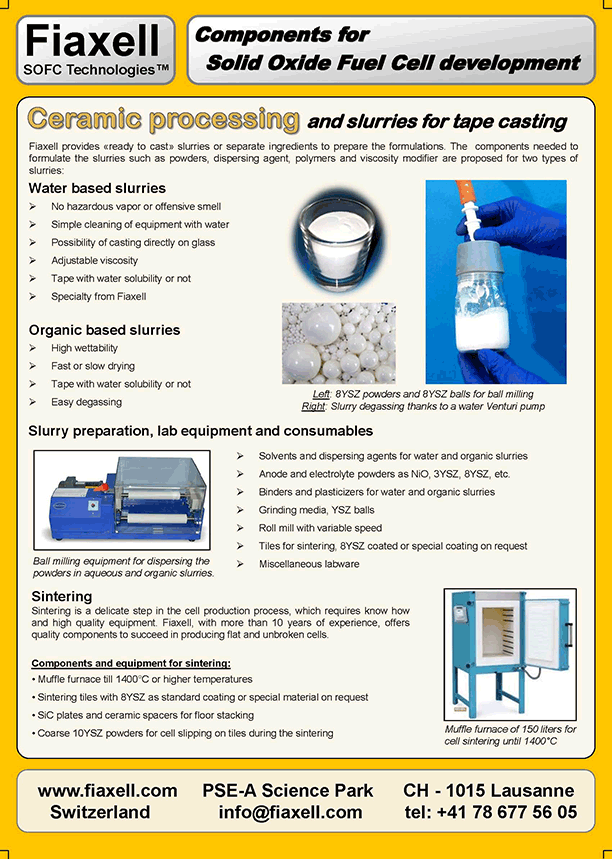

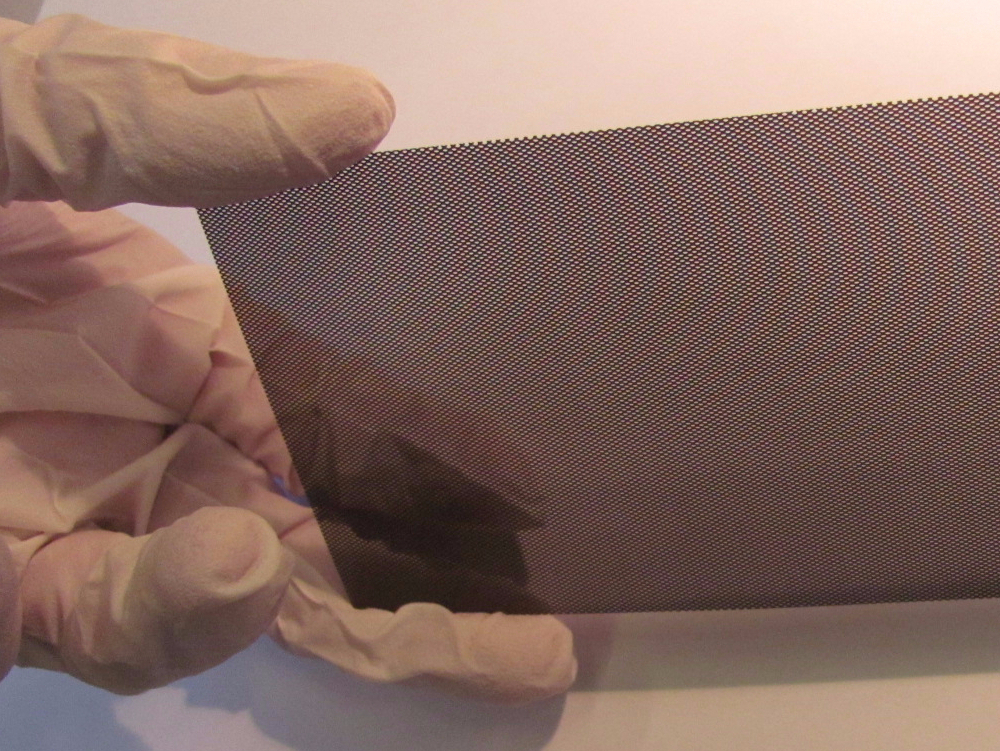

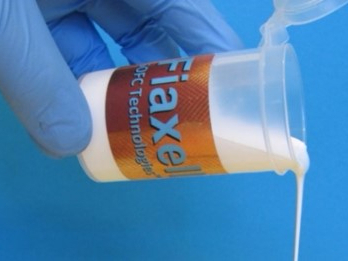

Fiaxell provides «ready to cast» slurries or separate ingredients to prepare the formulations. The components needed to formulate the slurries such as powders, pore formers, dispersing agents, polymers and viscosity modifiers are proposed for two types of slurries:

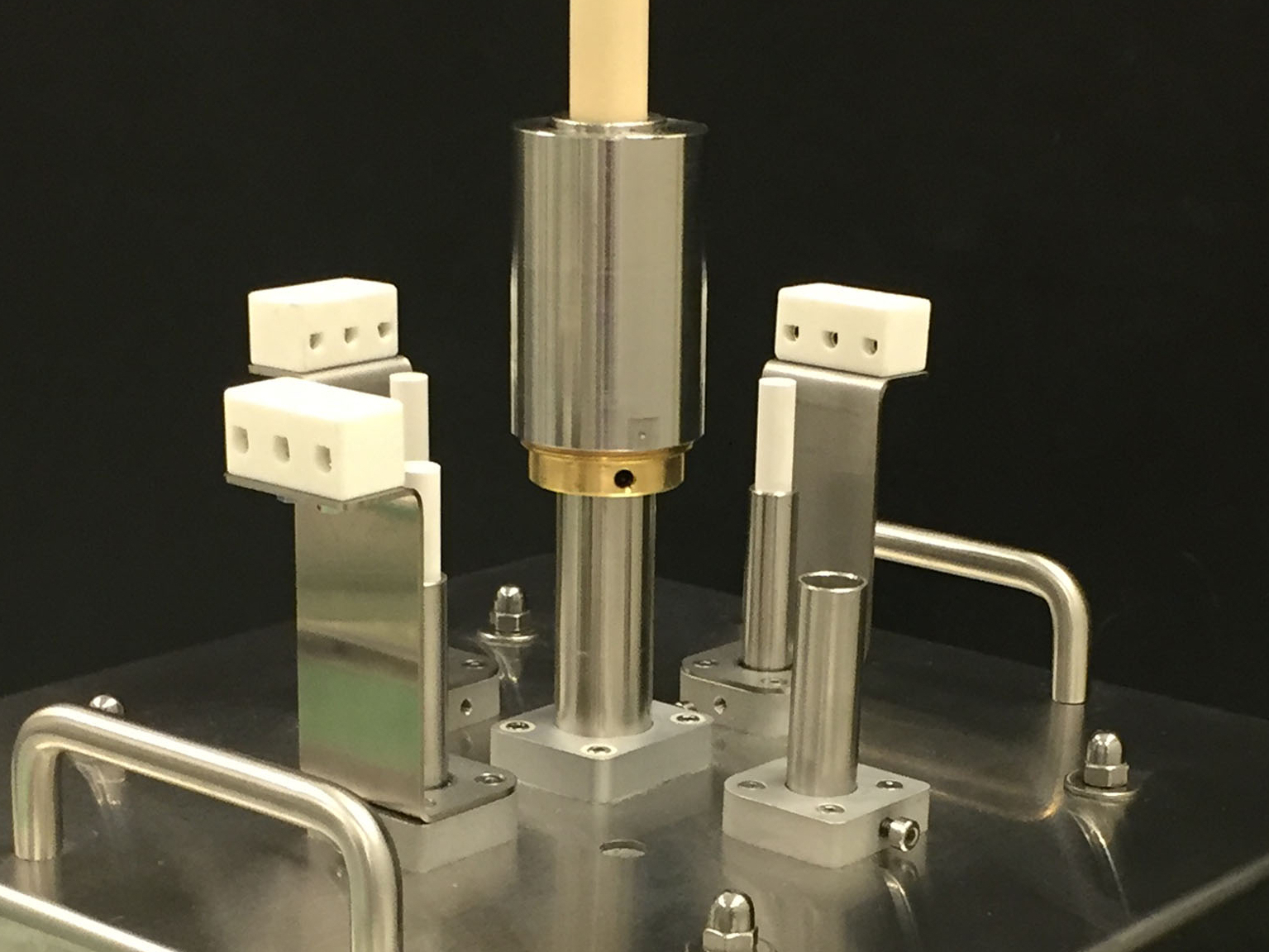

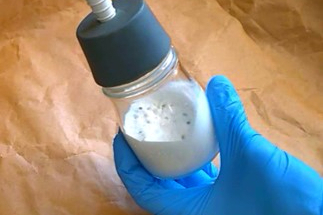

Slurry degassing thanks to a water Venturi pumpWater based slurries:

Slurry degassing thanks to a water Venturi pumpWater based slurries:

- No hazardous vapor or offensive smell

- Simple cleaning of equipment with water

- Possibility of casting directly on glass

- Adjustable viscosity

- Tape with water solubility or not

- Specialty from Fiaxell

Organic based slurries:

- High wettability

- Fast or slow drying

- Tape with water solubility or not

- Easy degassing

Slurry preparation, lab equipment and consumables:

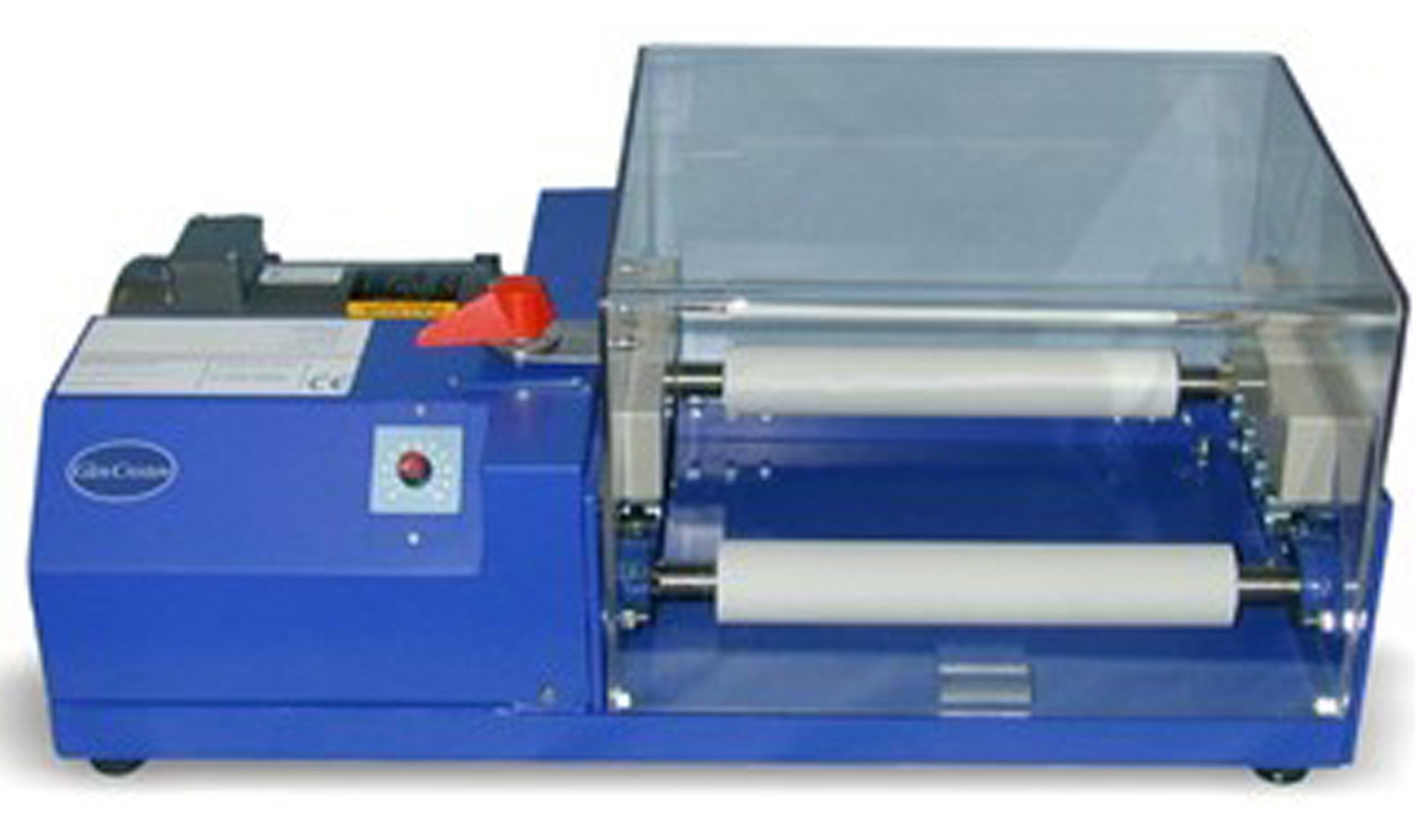

Fiaxell also provides all the necessary equipment for tape casting slurry preparation: Ball milling equipment for dispersing the powders in aqueous and organic slurries. The rolls can be moved in function of the jar diameter

Ball milling equipment for dispersing the powders in aqueous and organic slurries. The rolls can be moved in function of the jar diameter

- Anode and electrolyte powders as NiO, 3YSZ, 8YSZ, etc. (see powders)

- Solvents and dispersing agents for water and organic slurries

- Binders and plasticizers for water and organic slurries

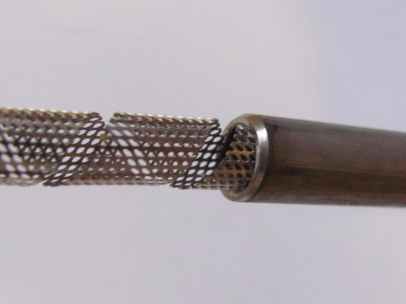

- Grinding media, YSZ balls

- Roll mill with variable speed

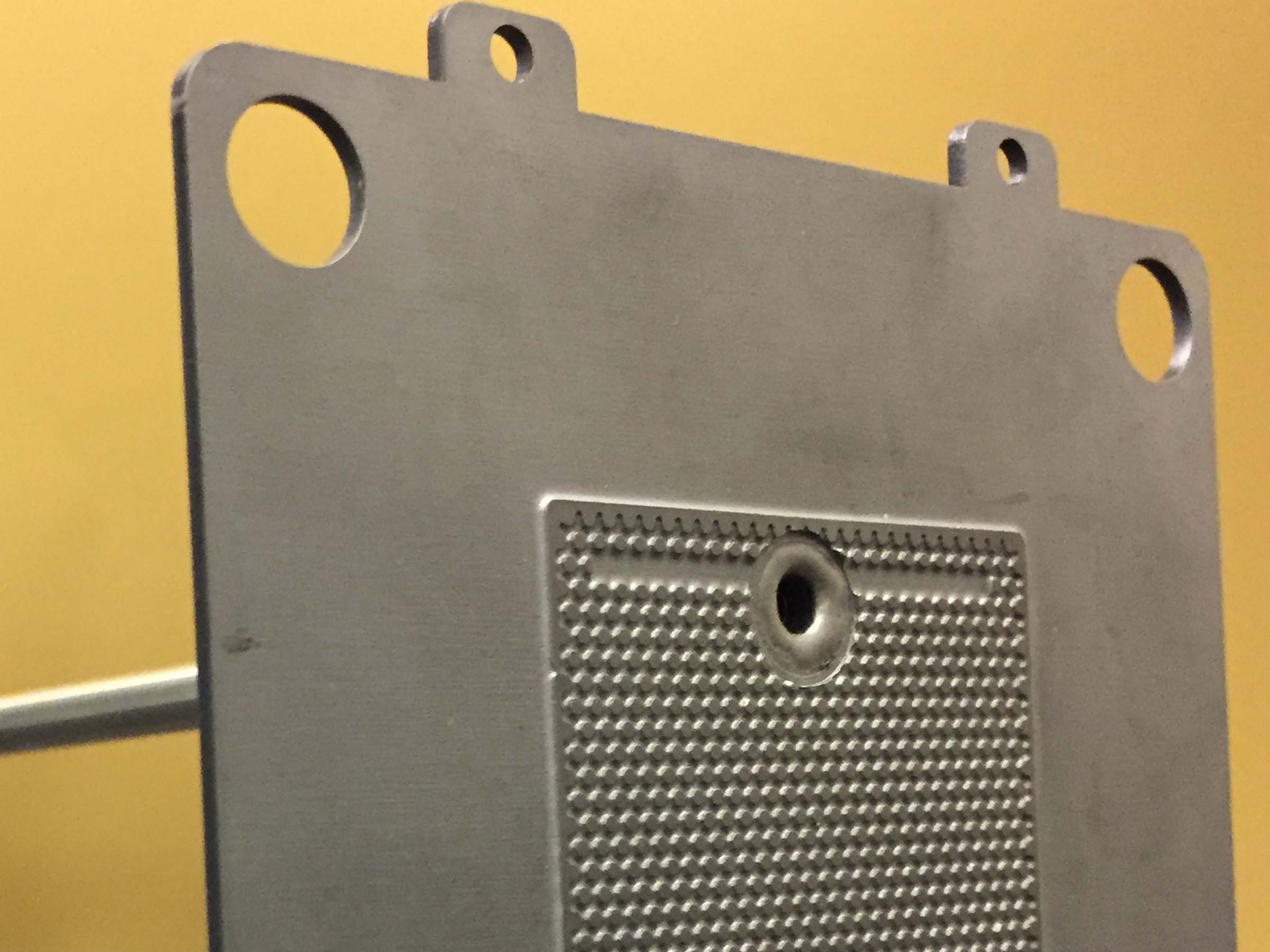

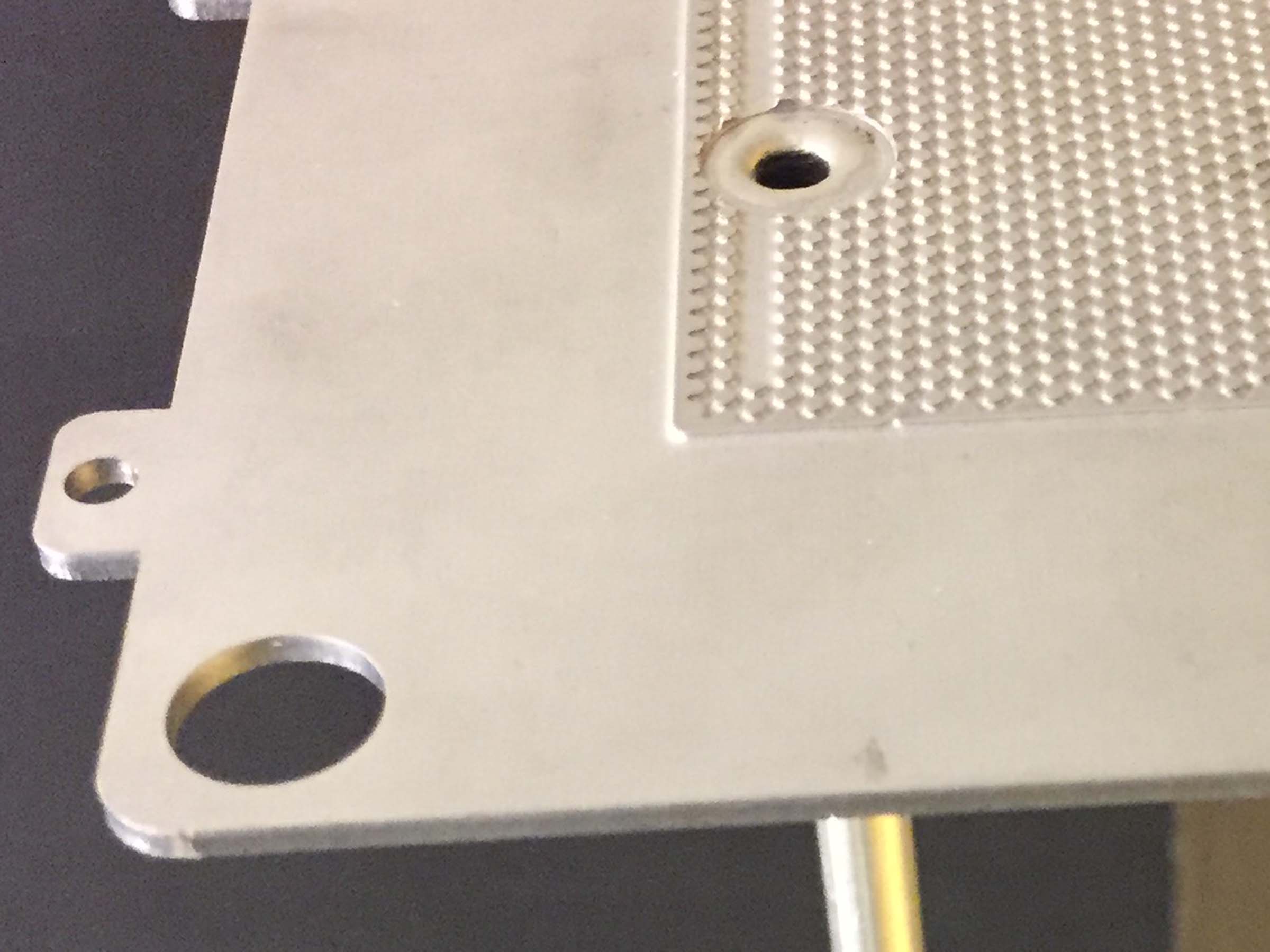

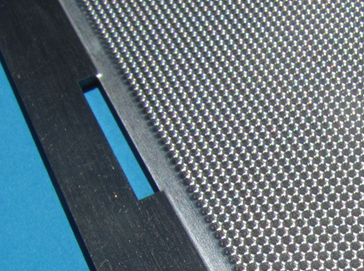

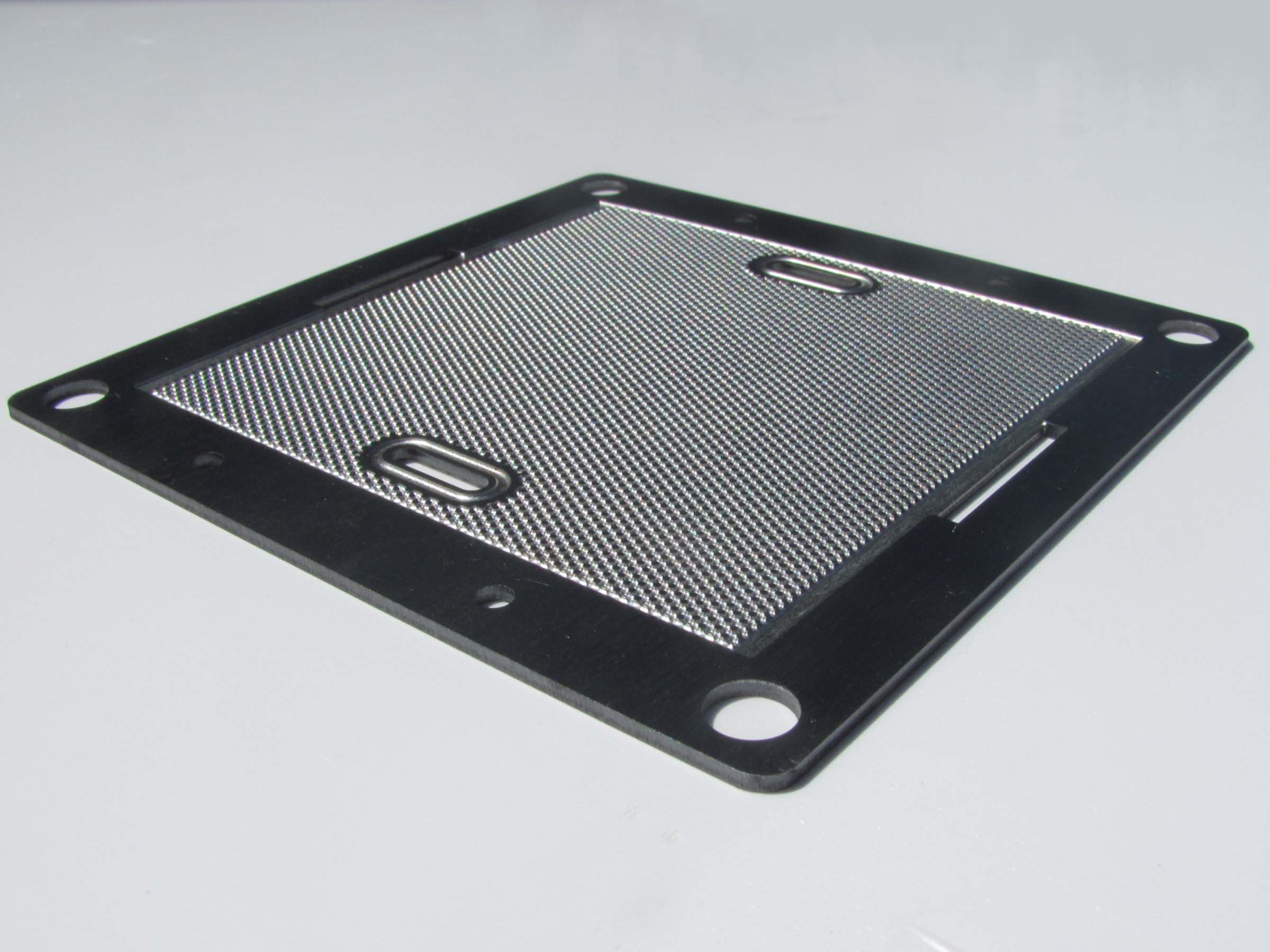

- Tiles for sintering, 8YSZ coated or special coating on request (NiO, CeO2, MgO, BCY, etc)

- Miscellaneous labware

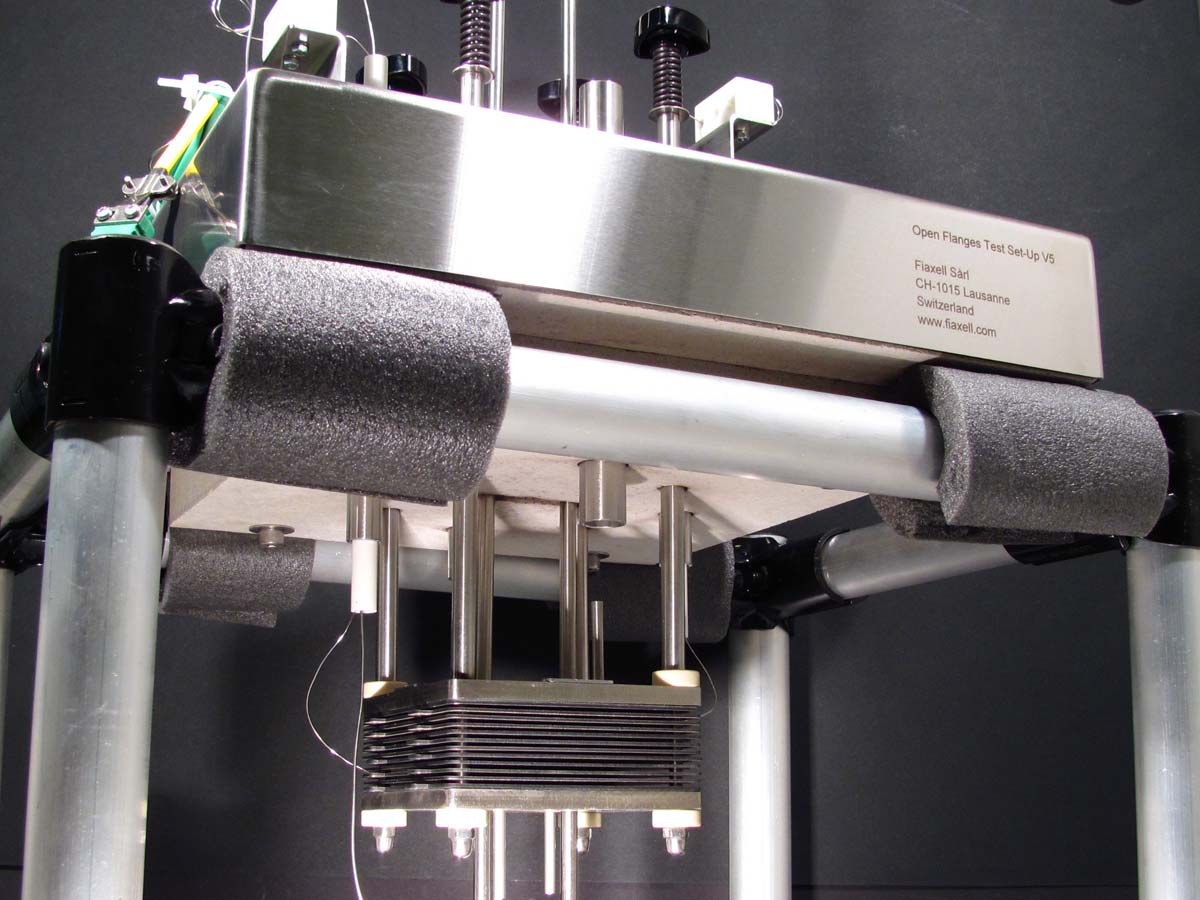

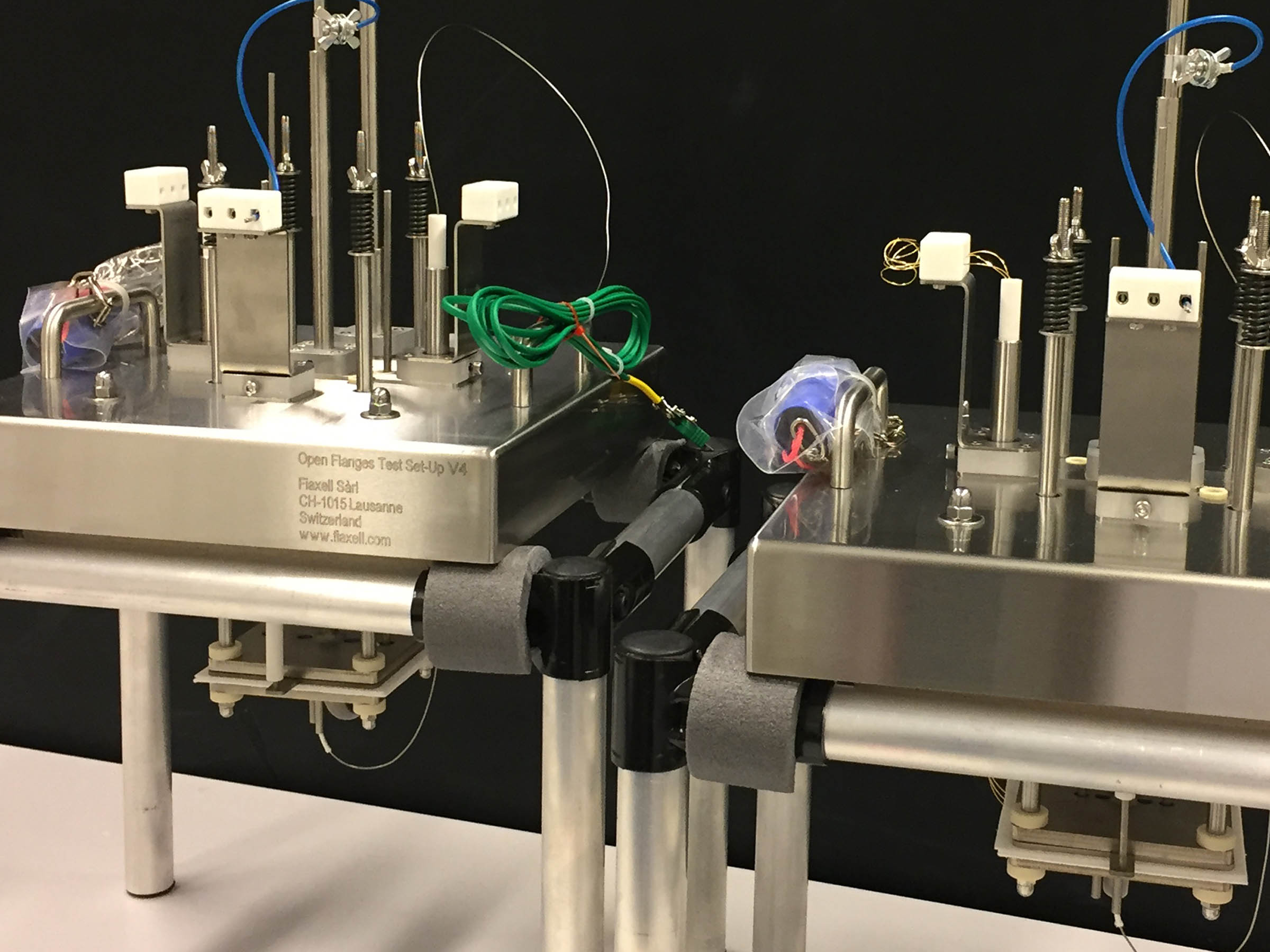

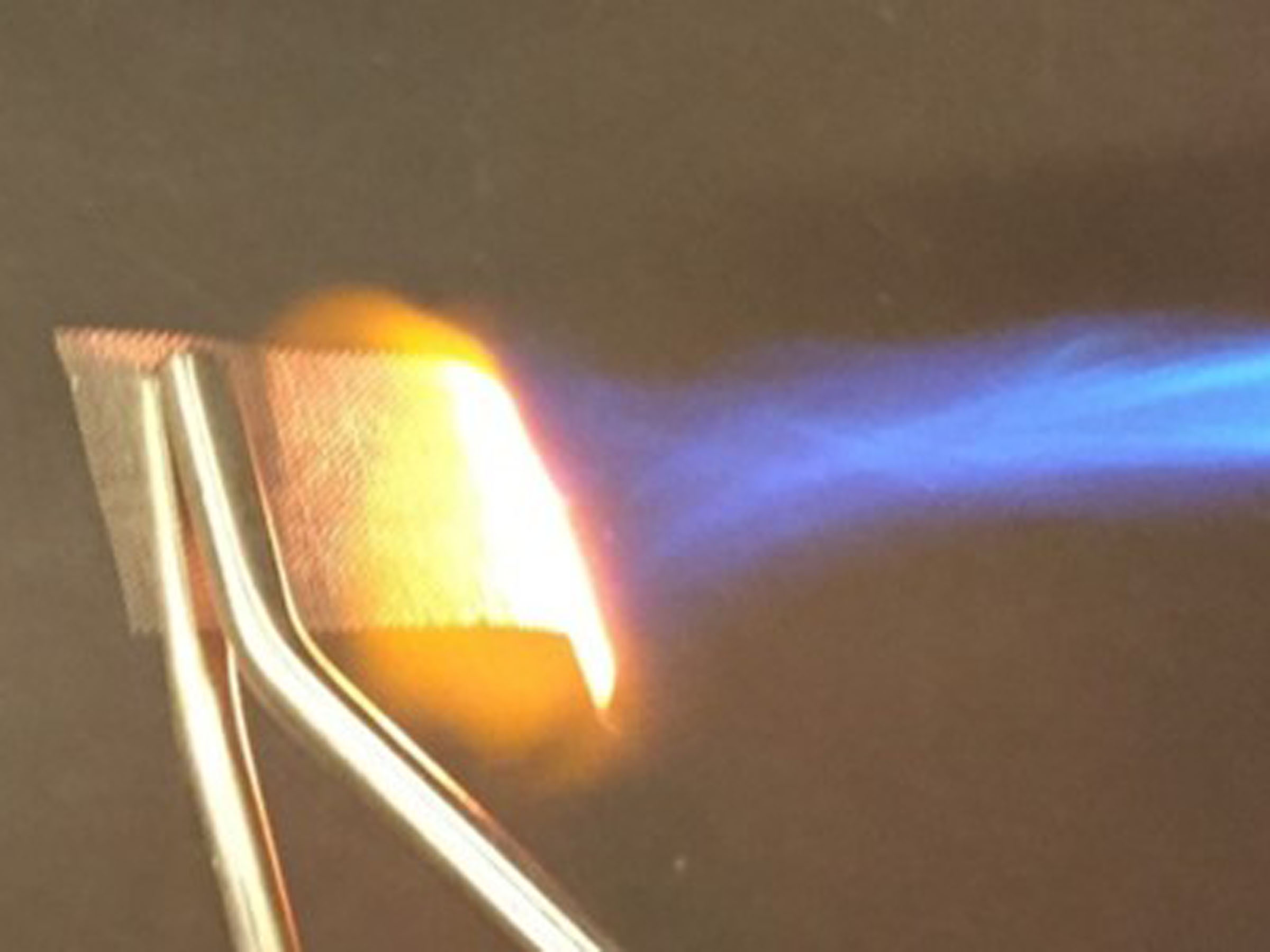

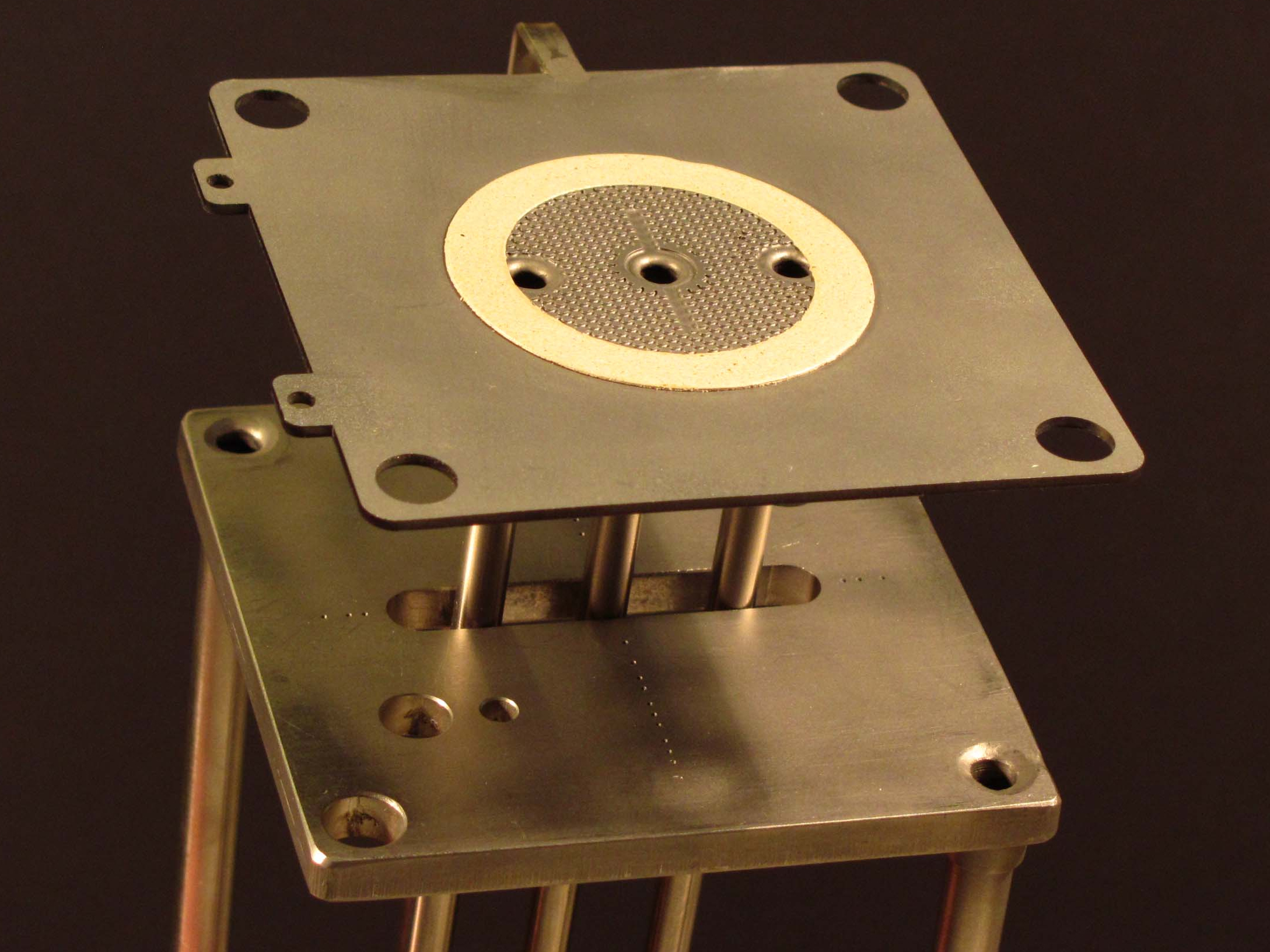

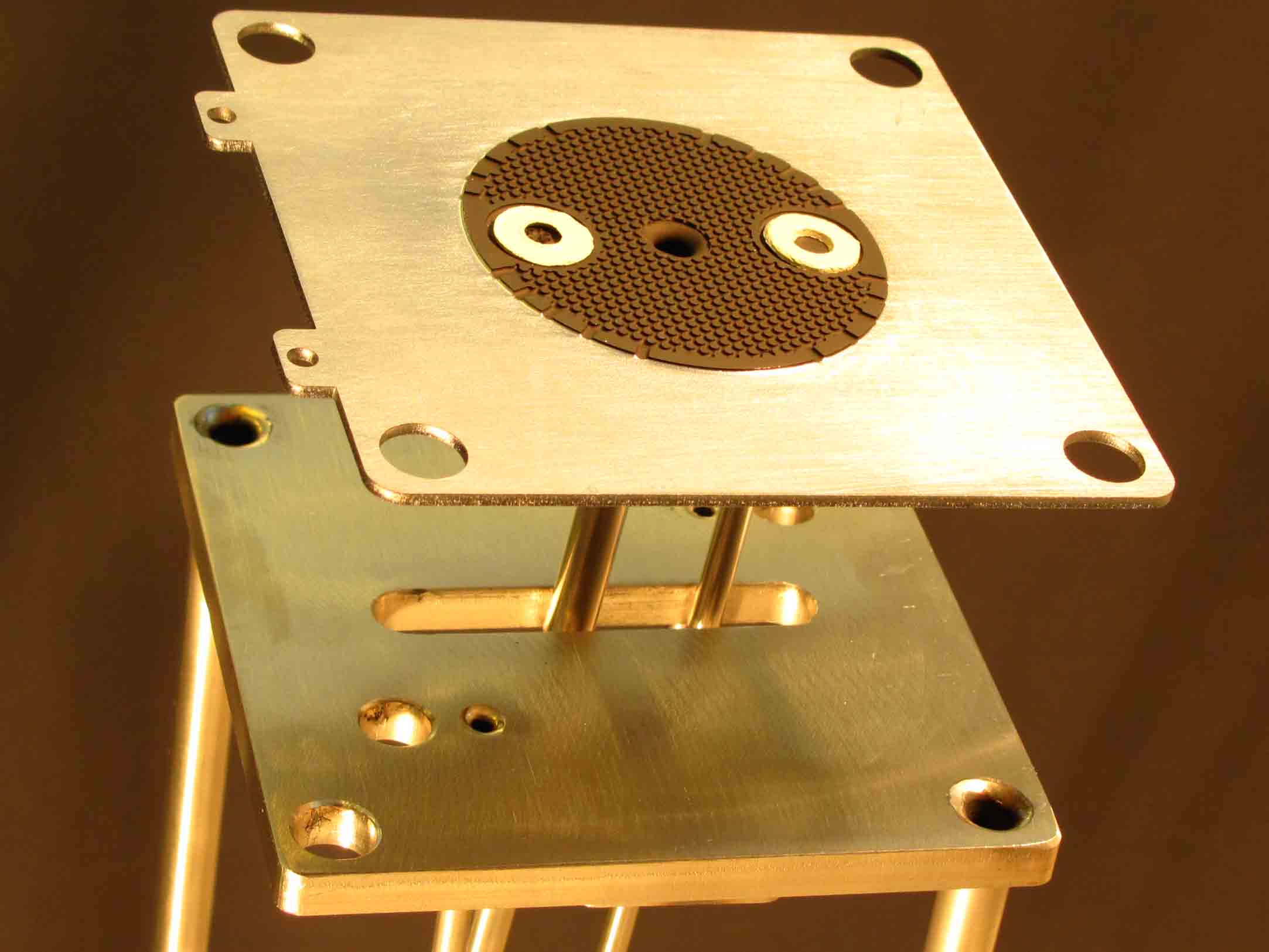

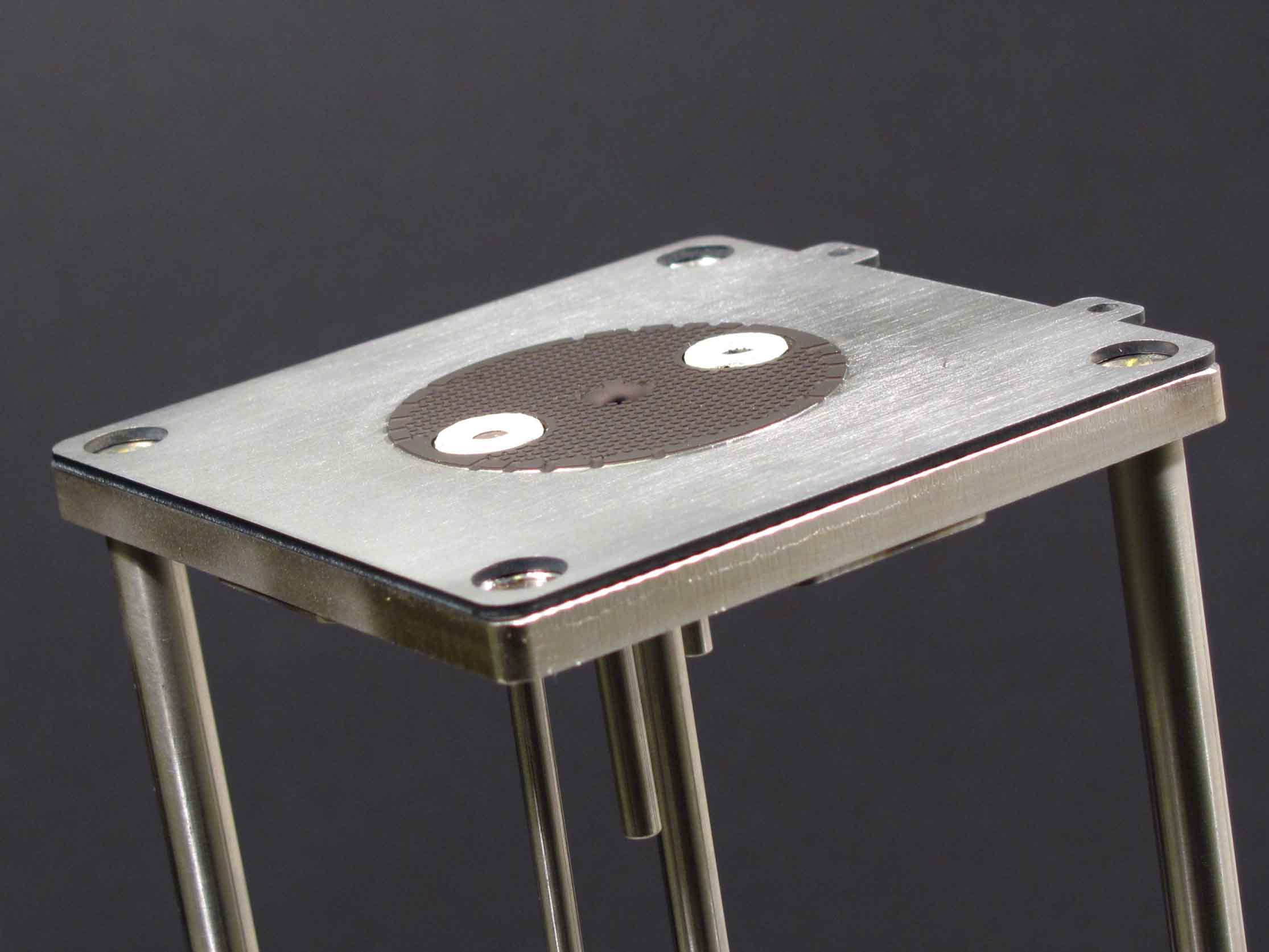

Sintering:

Sintering is a delicate step in the cell production process, which requires know how and high quality equipment. Fiaxell, with more than 10 years of experience, offers quality components to succeed in producing flat and unbroken cells.

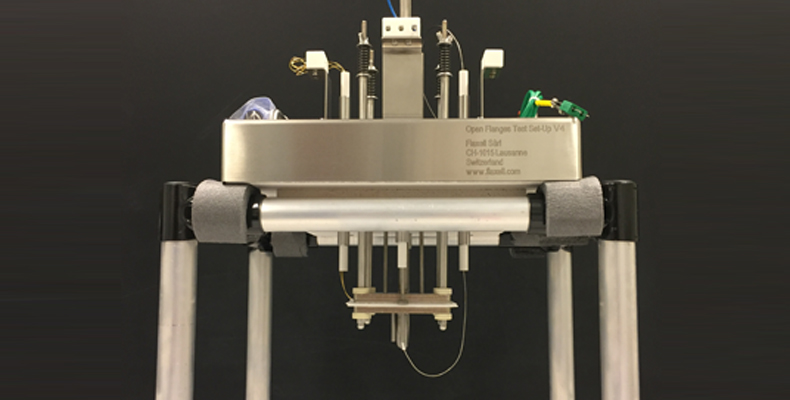

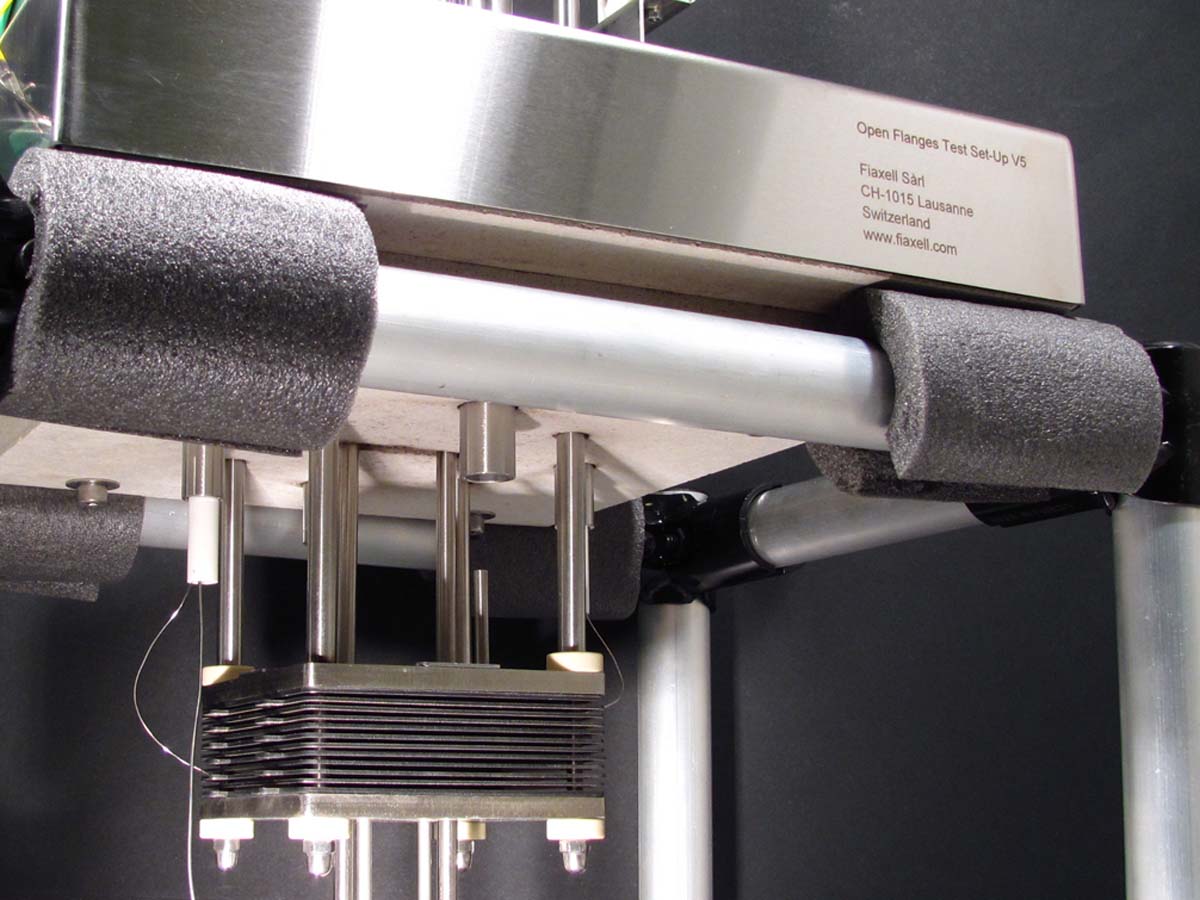

Components and equipment for sintering: Muffle furnace of 150 liters for cell sintering until 1400°C

Muffle furnace of 150 liters for cell sintering until 1400°C

- Muffle furnace till 1400°C or higher temperatures

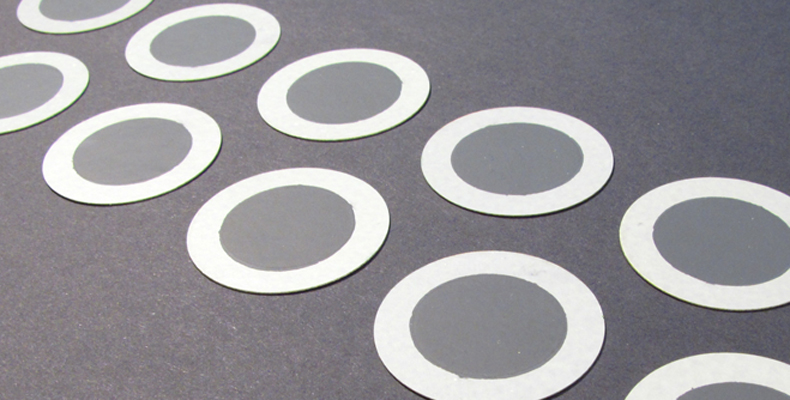

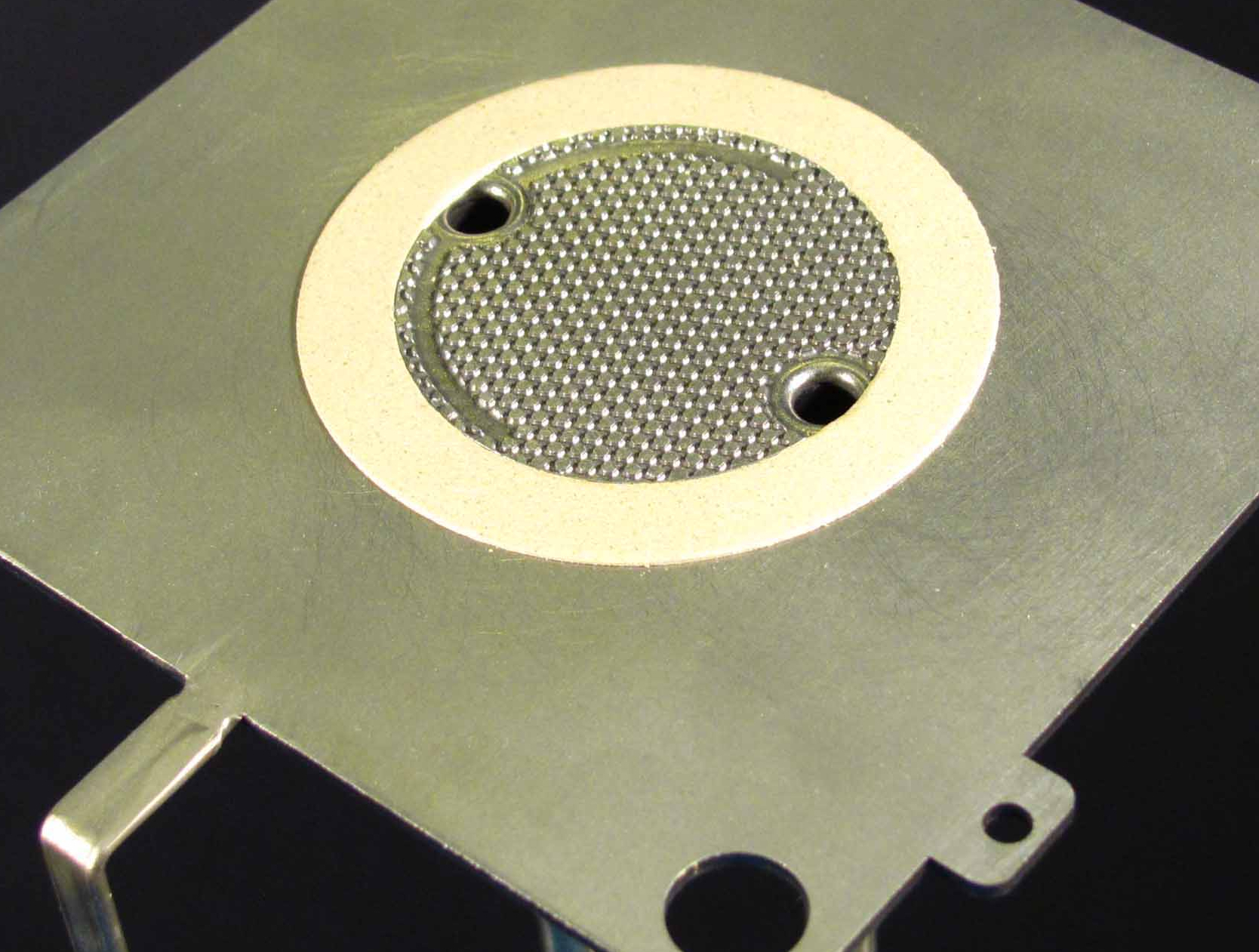

- Sintering tiles with 8YSZ as standard coating or special material on request (CeO2, NiO, MgO, BCY, etc.)

- SiC plates and ceramic spacers for floor stacking

- Coarse 10YSZ powders for cell slipping on tiles during the sintering

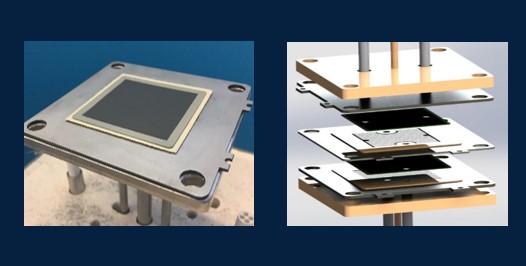

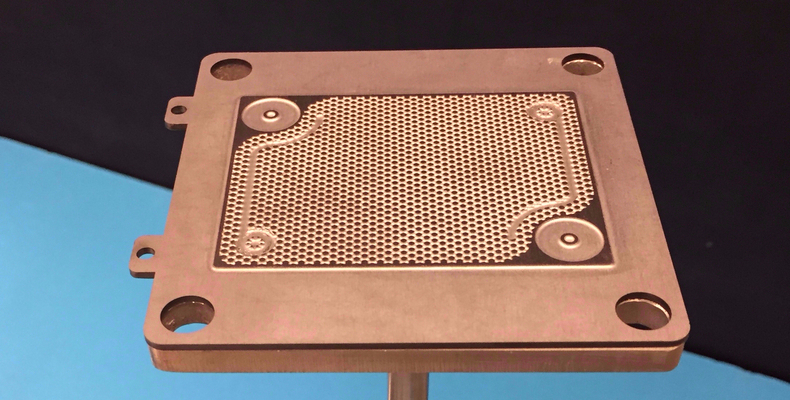

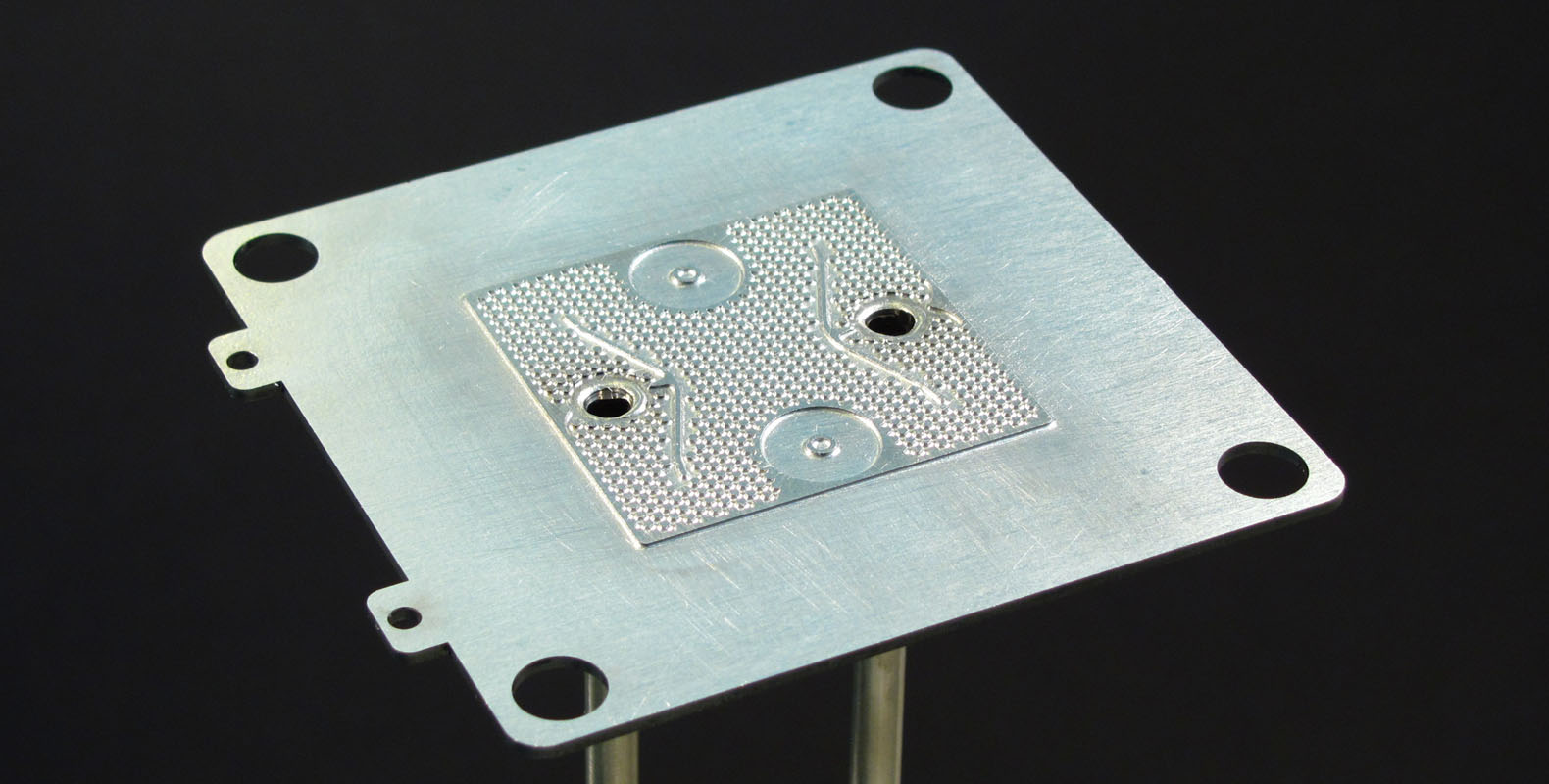

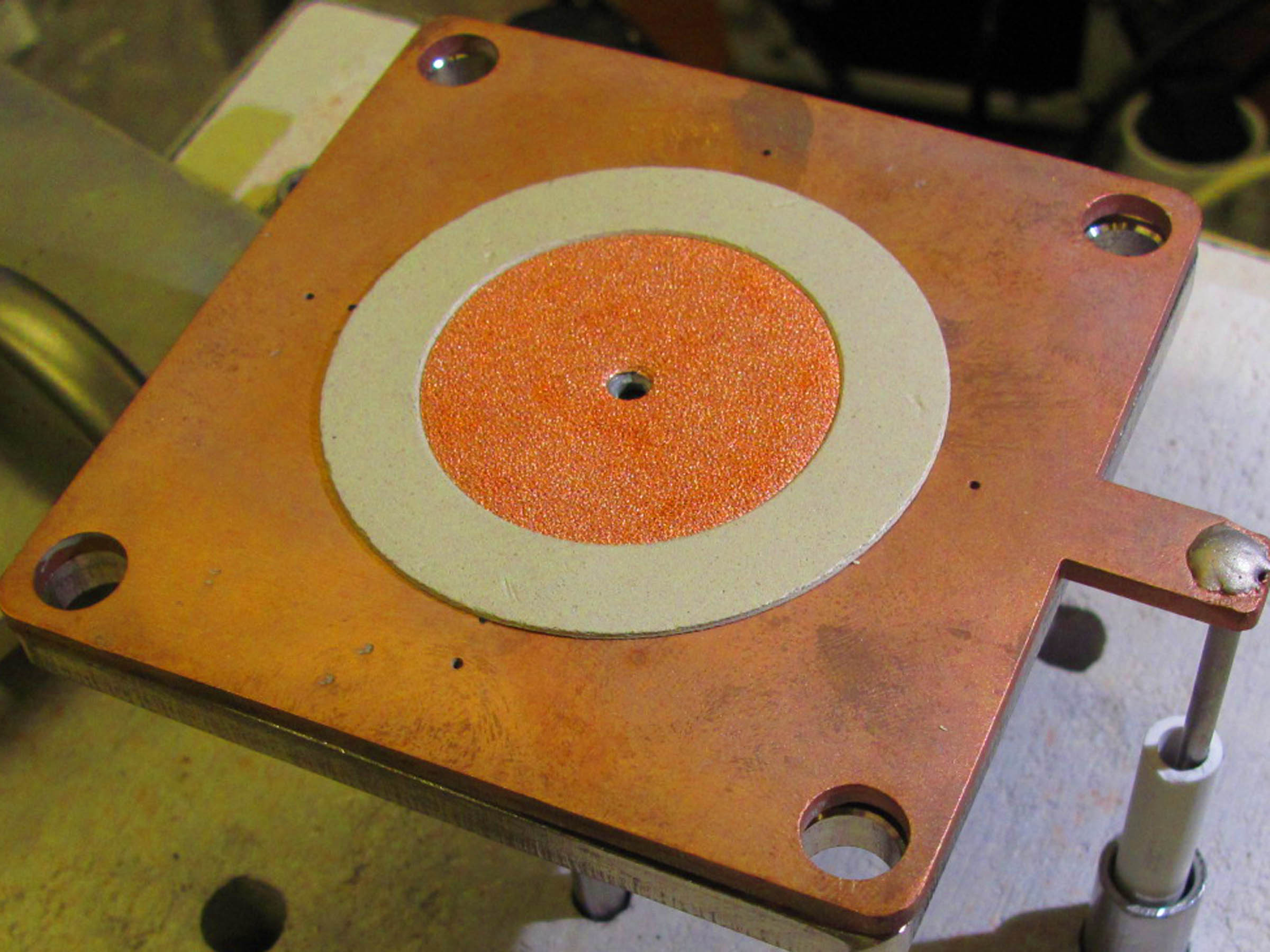

Cell fabrication:

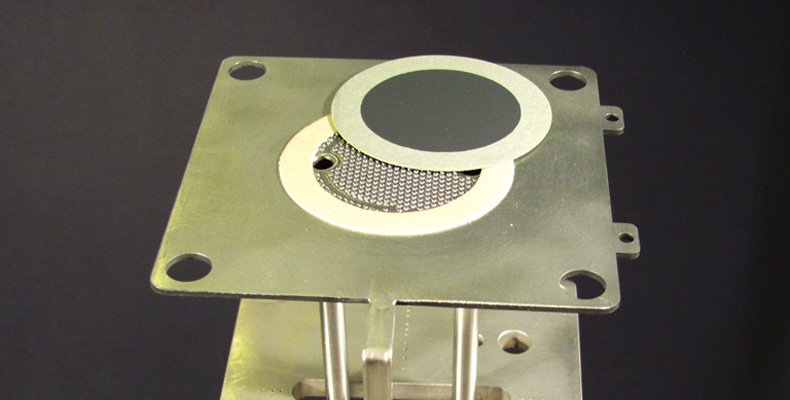

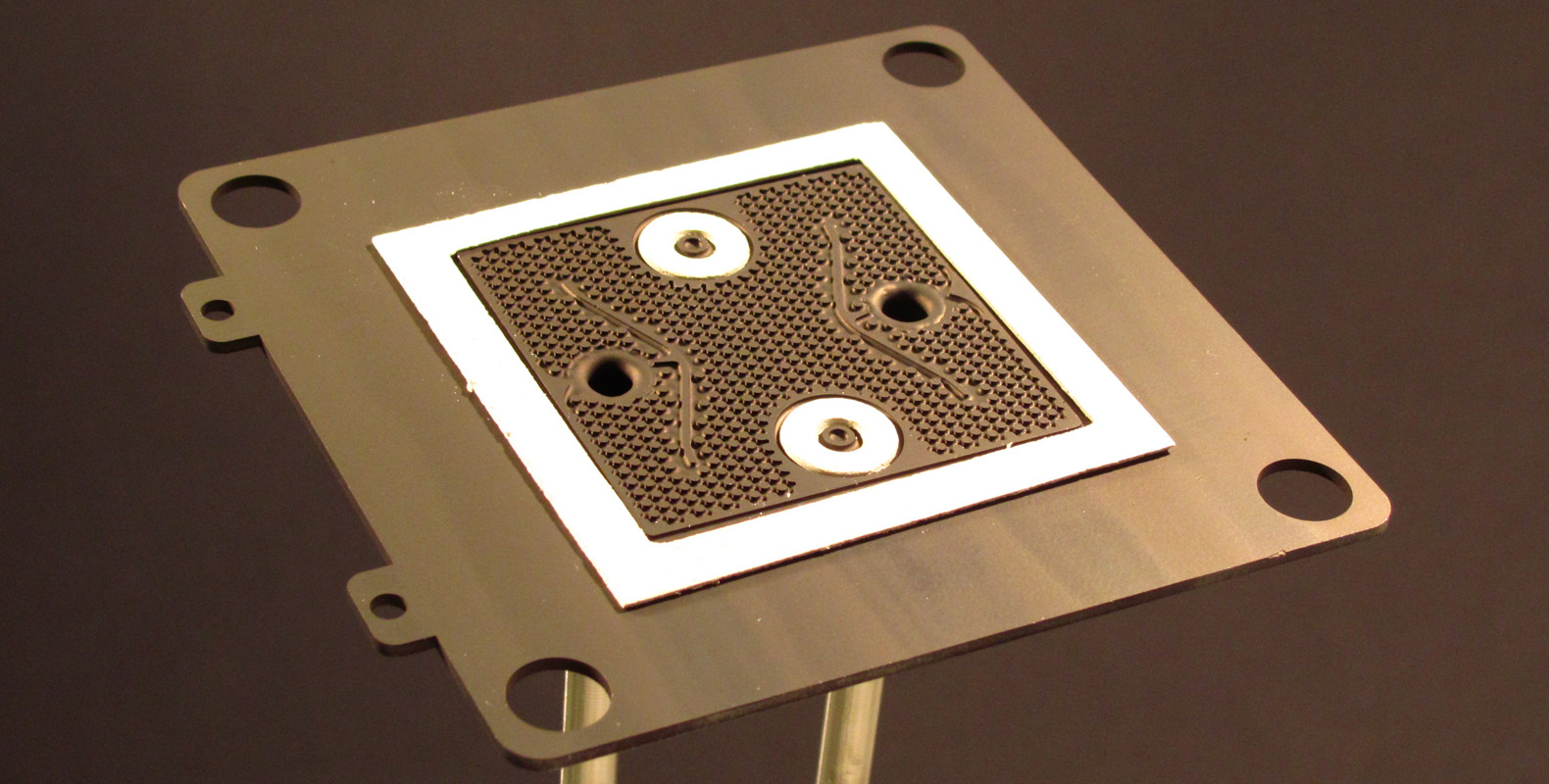

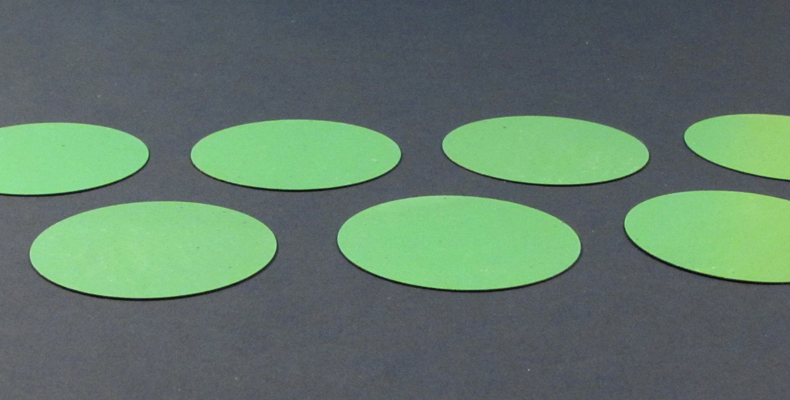

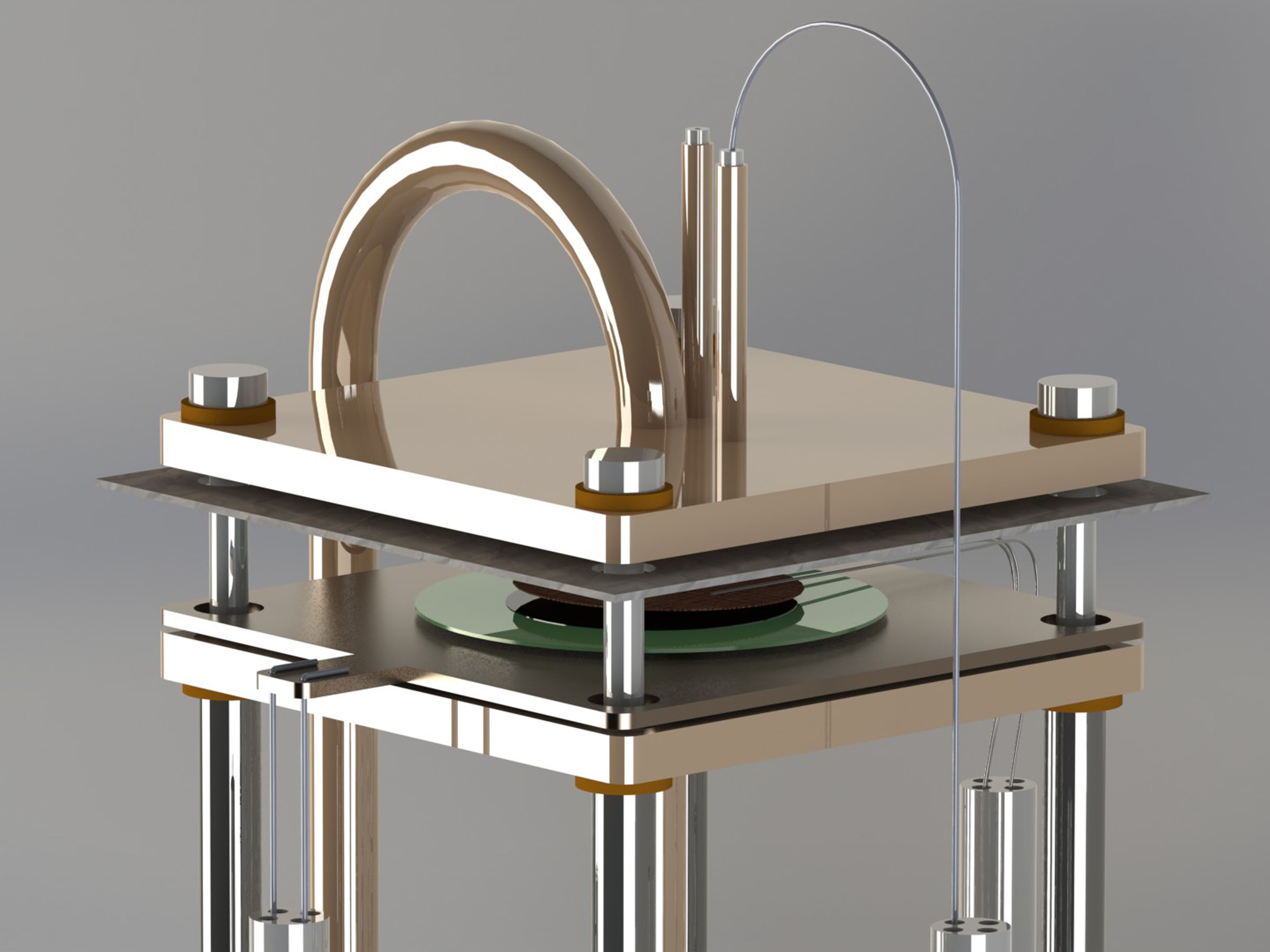

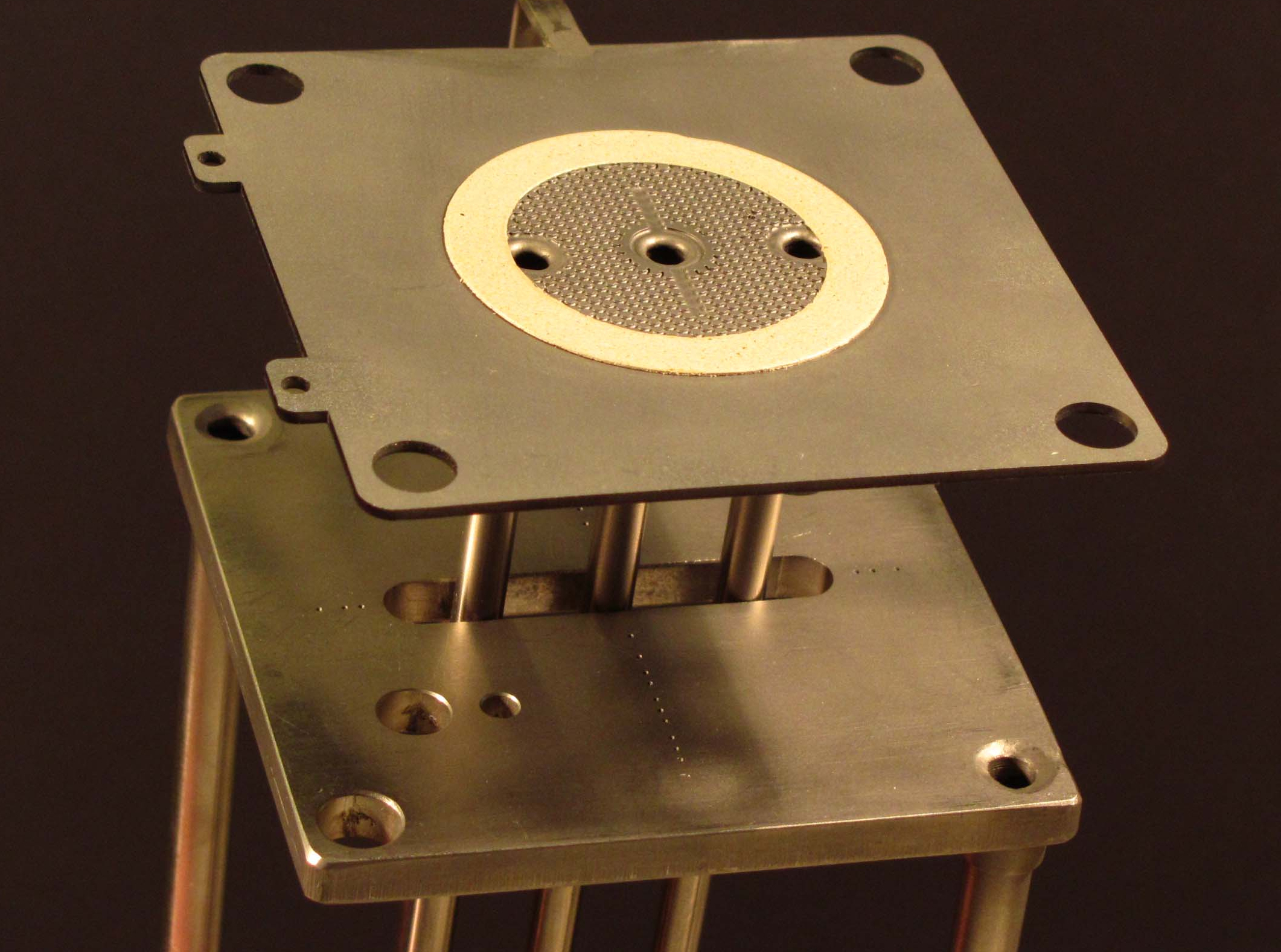

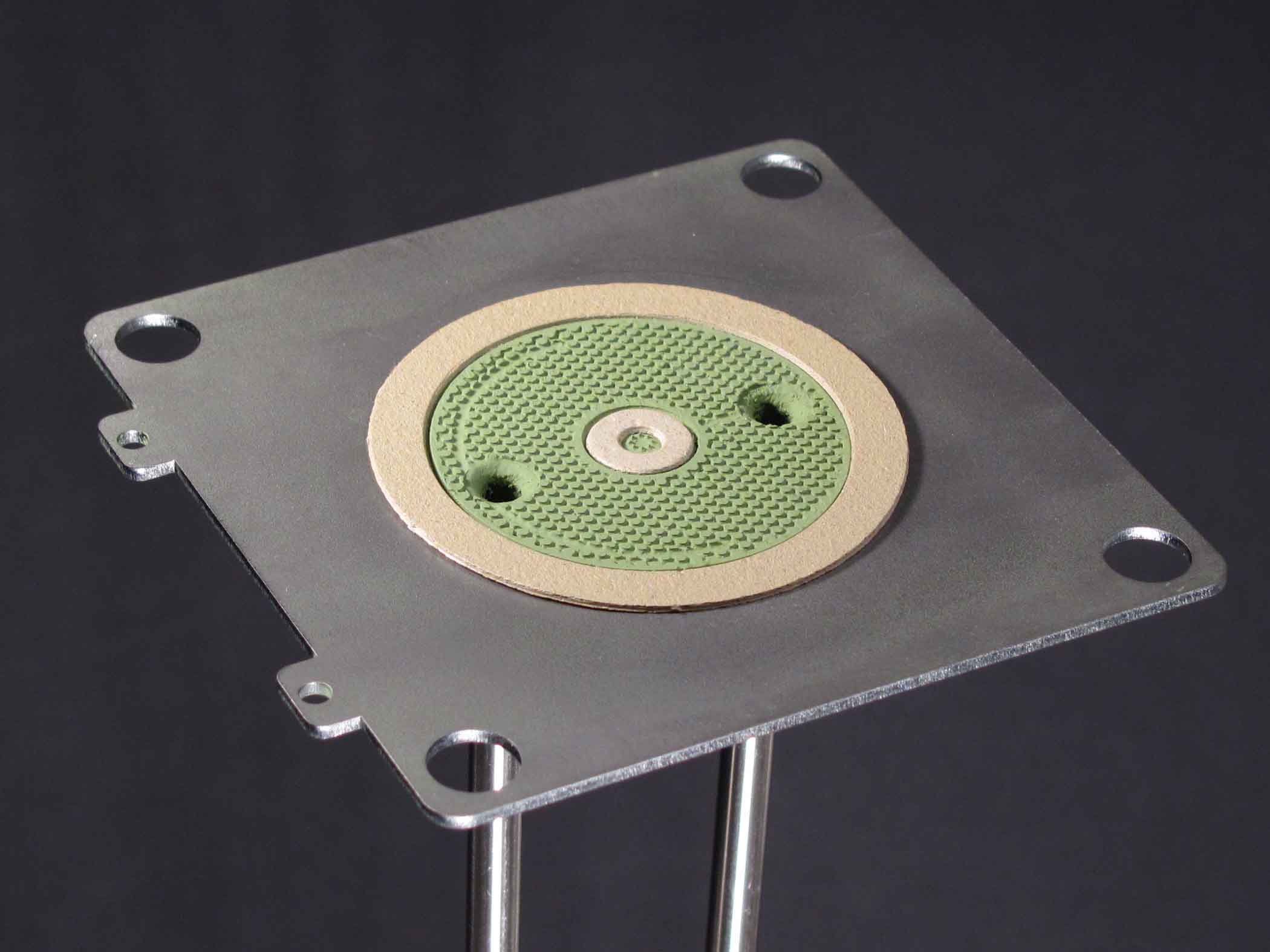

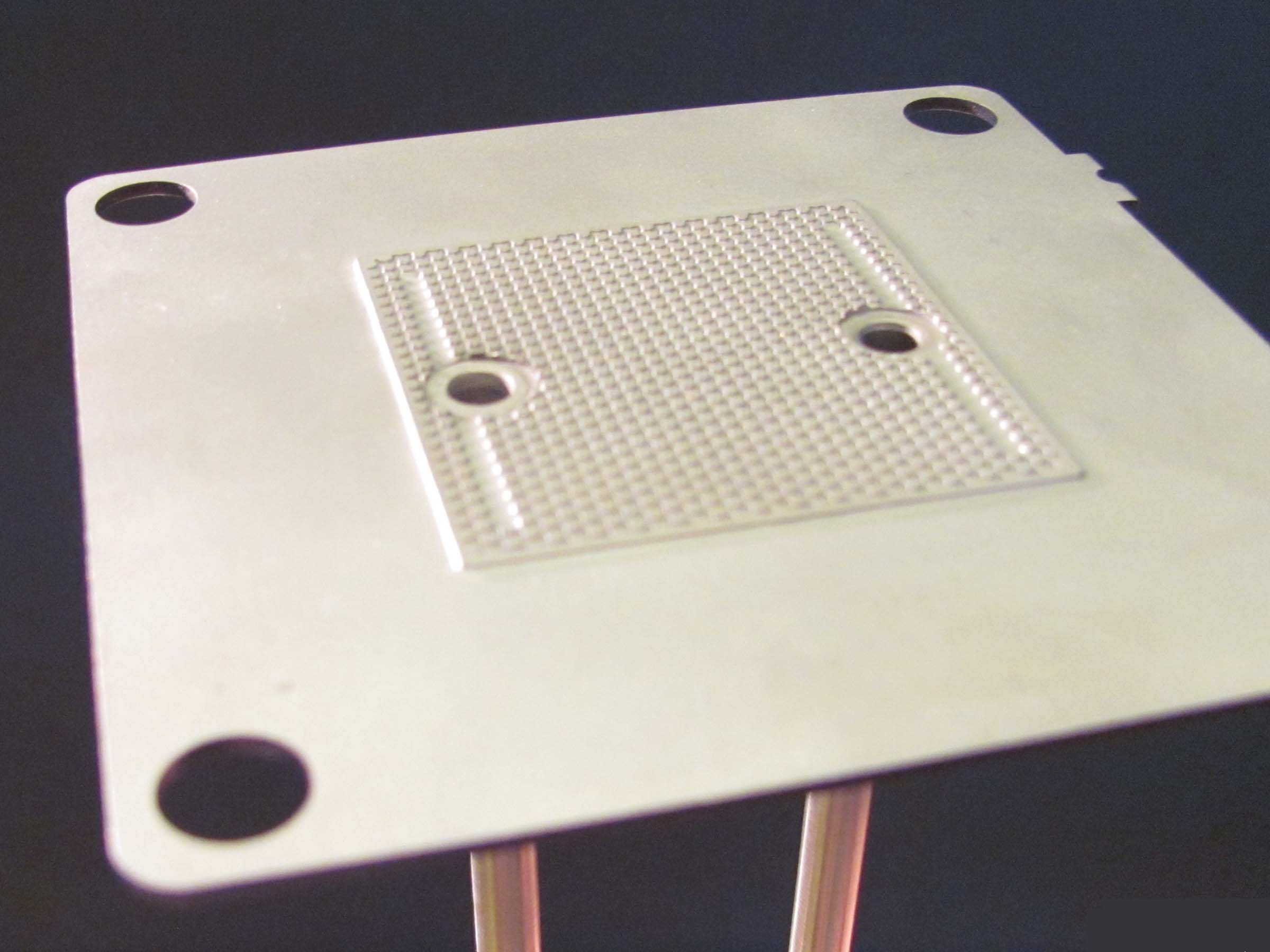

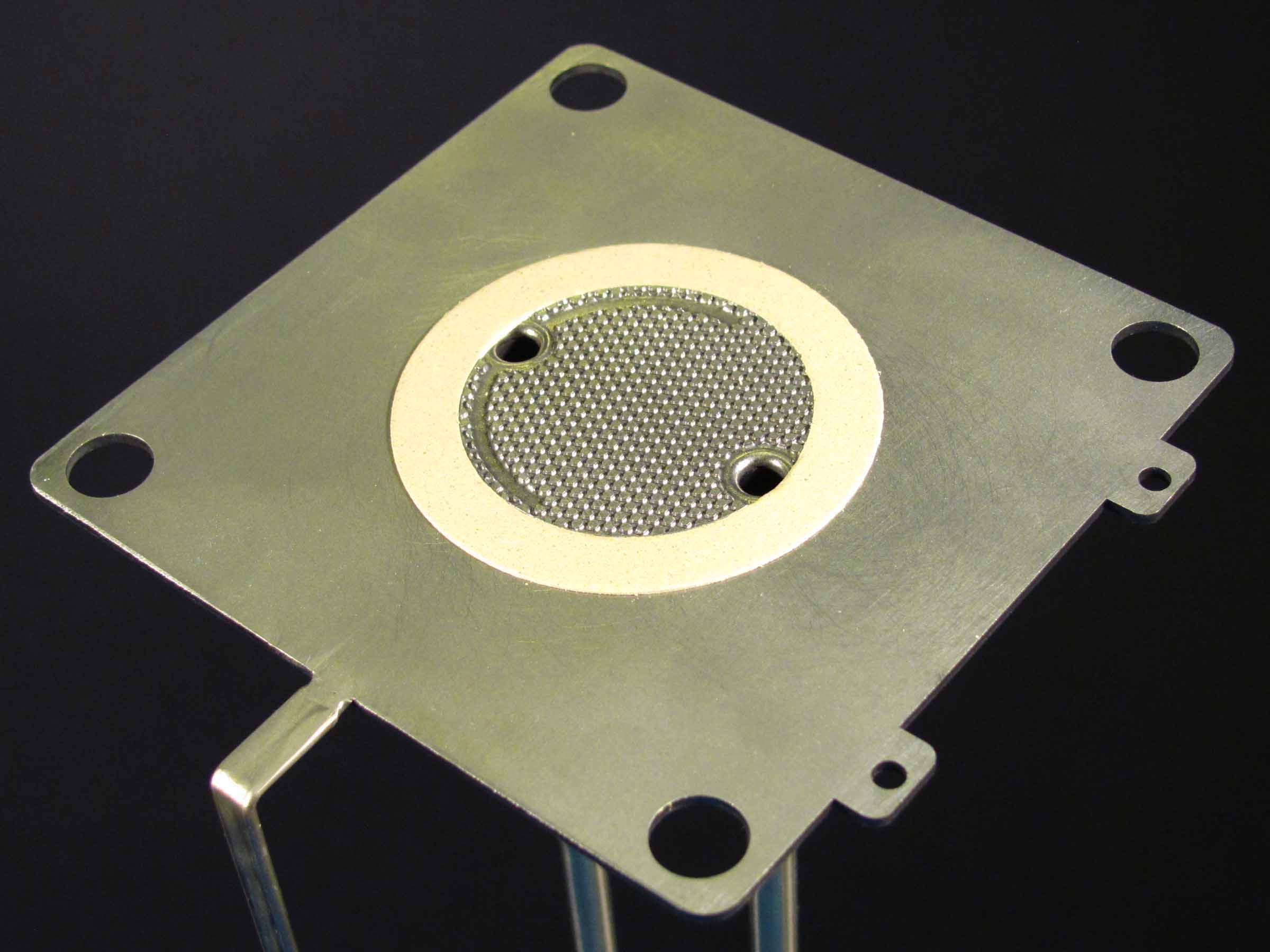

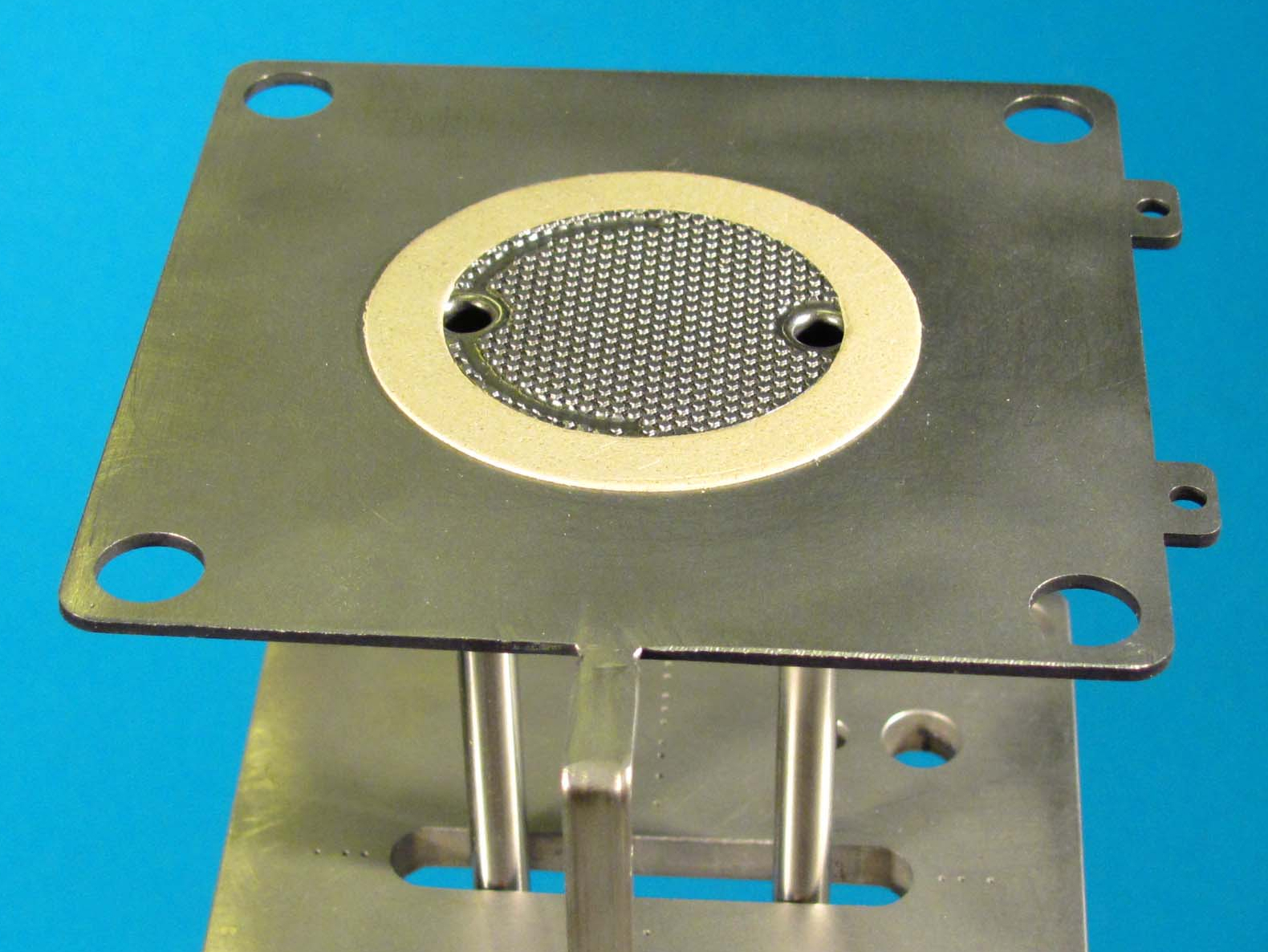

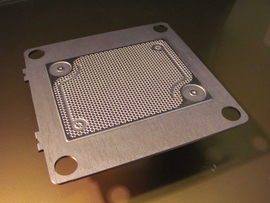

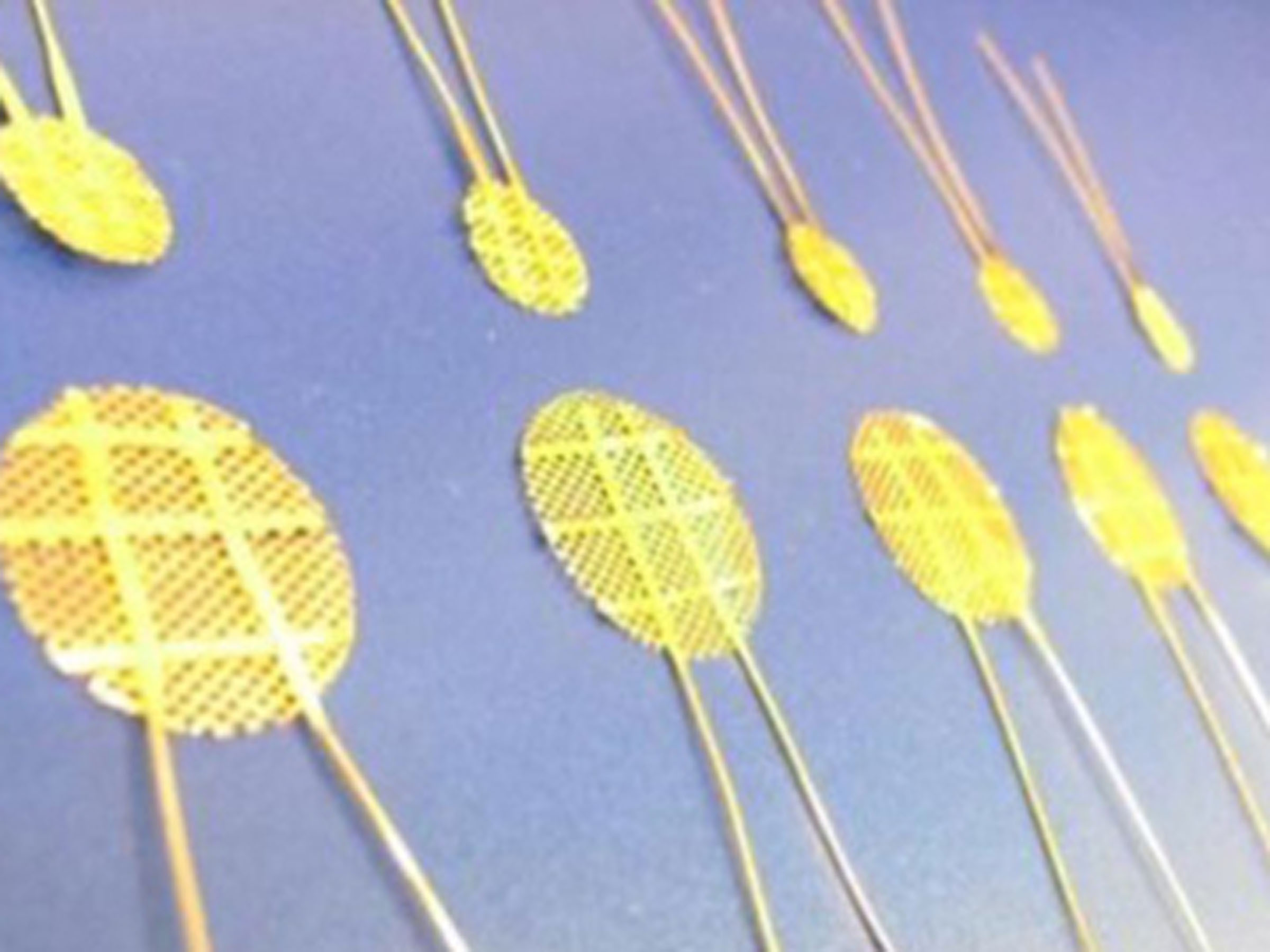

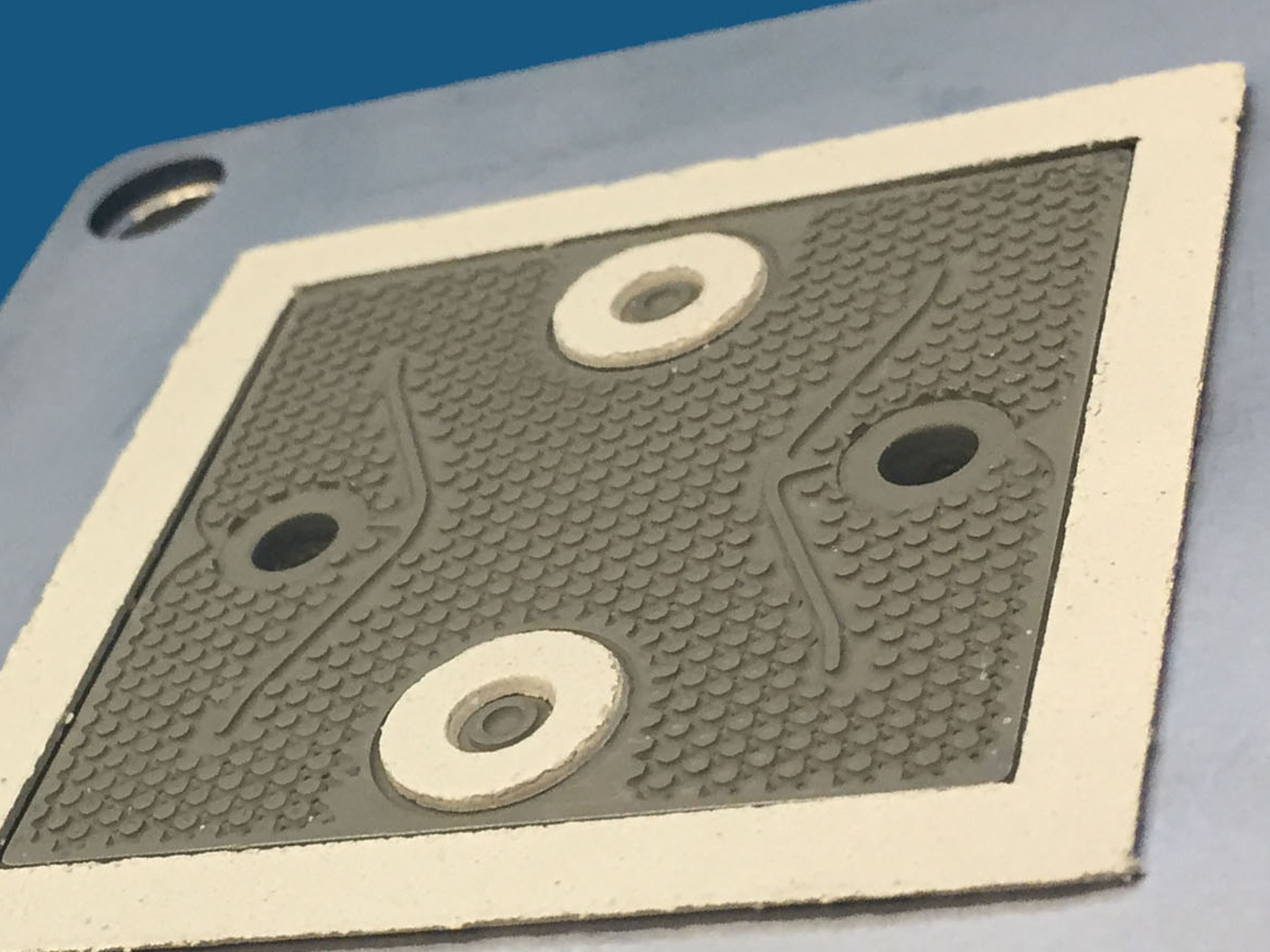

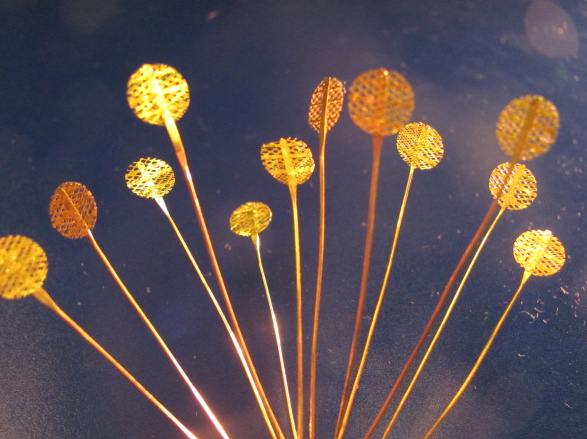

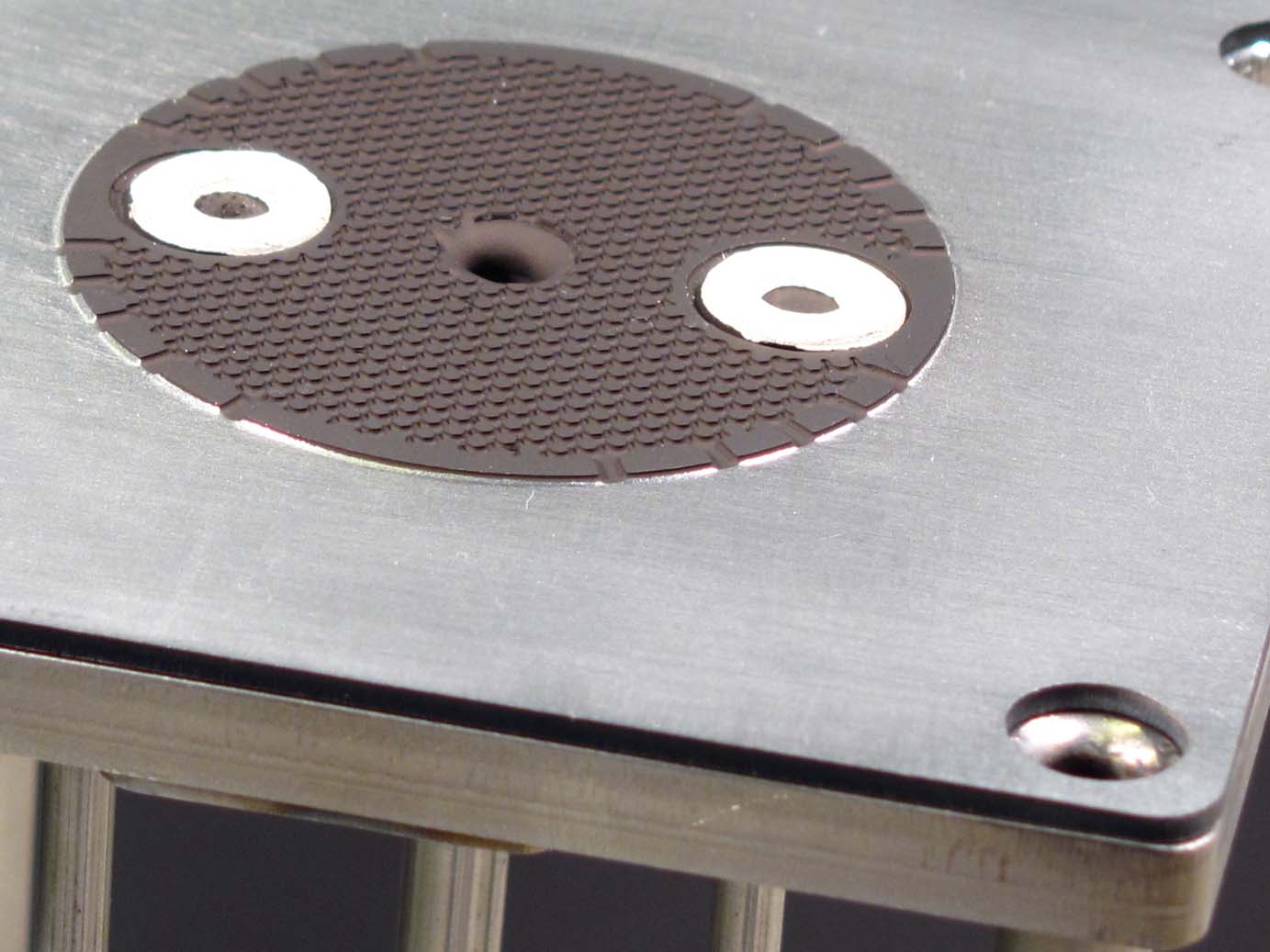

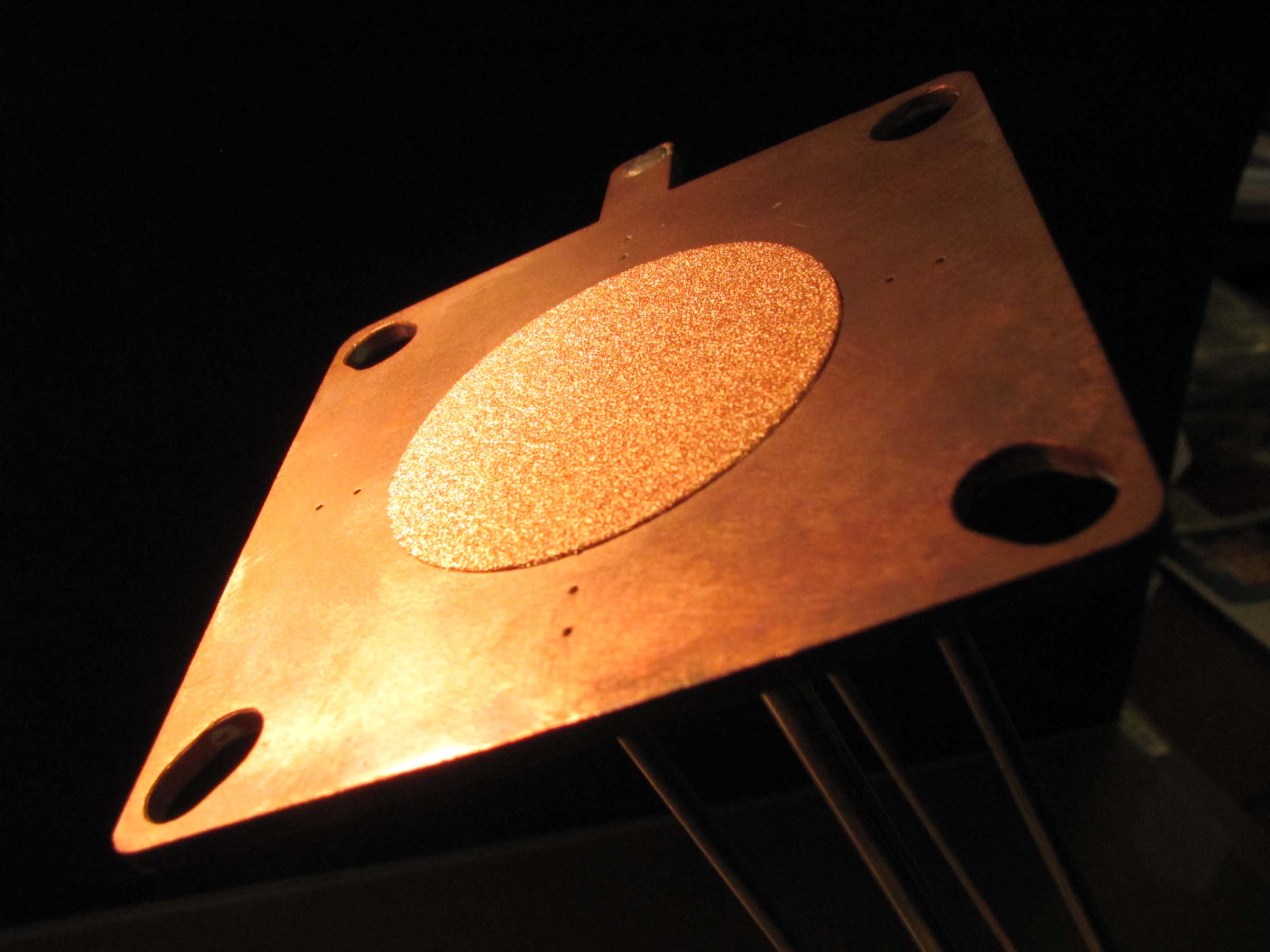

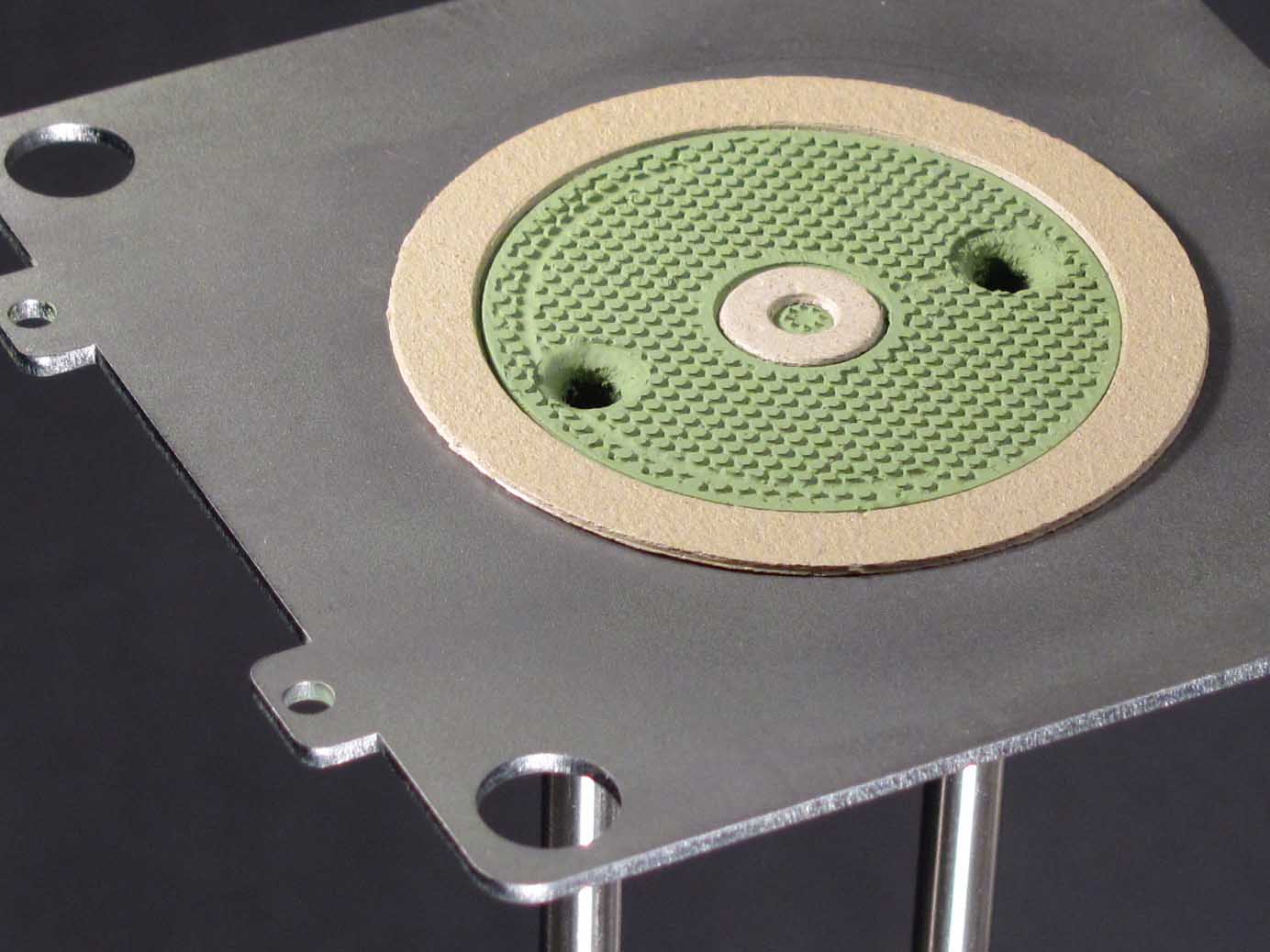

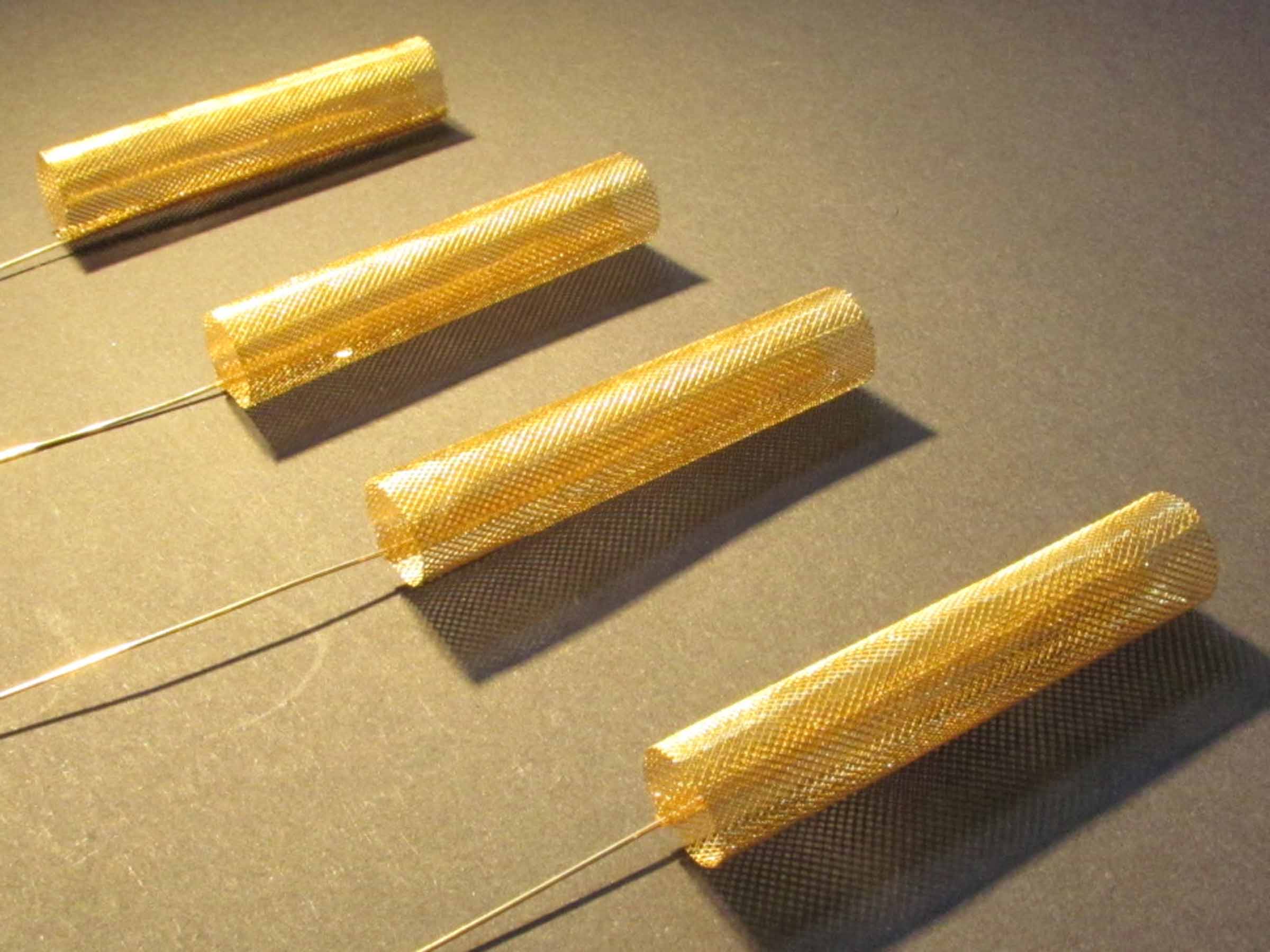

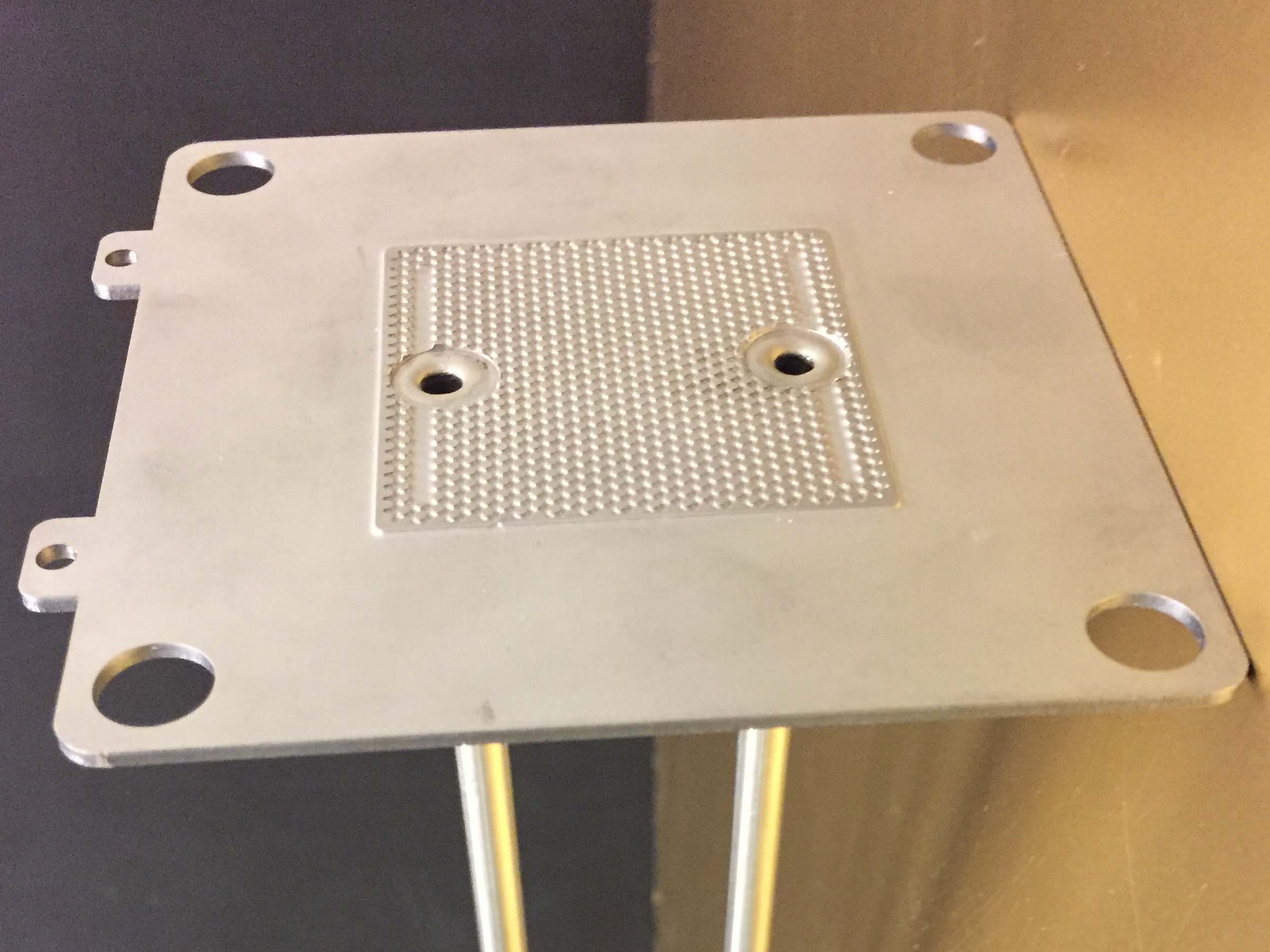

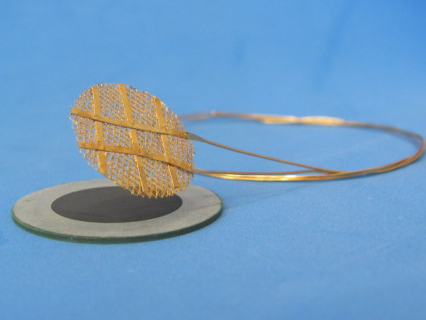

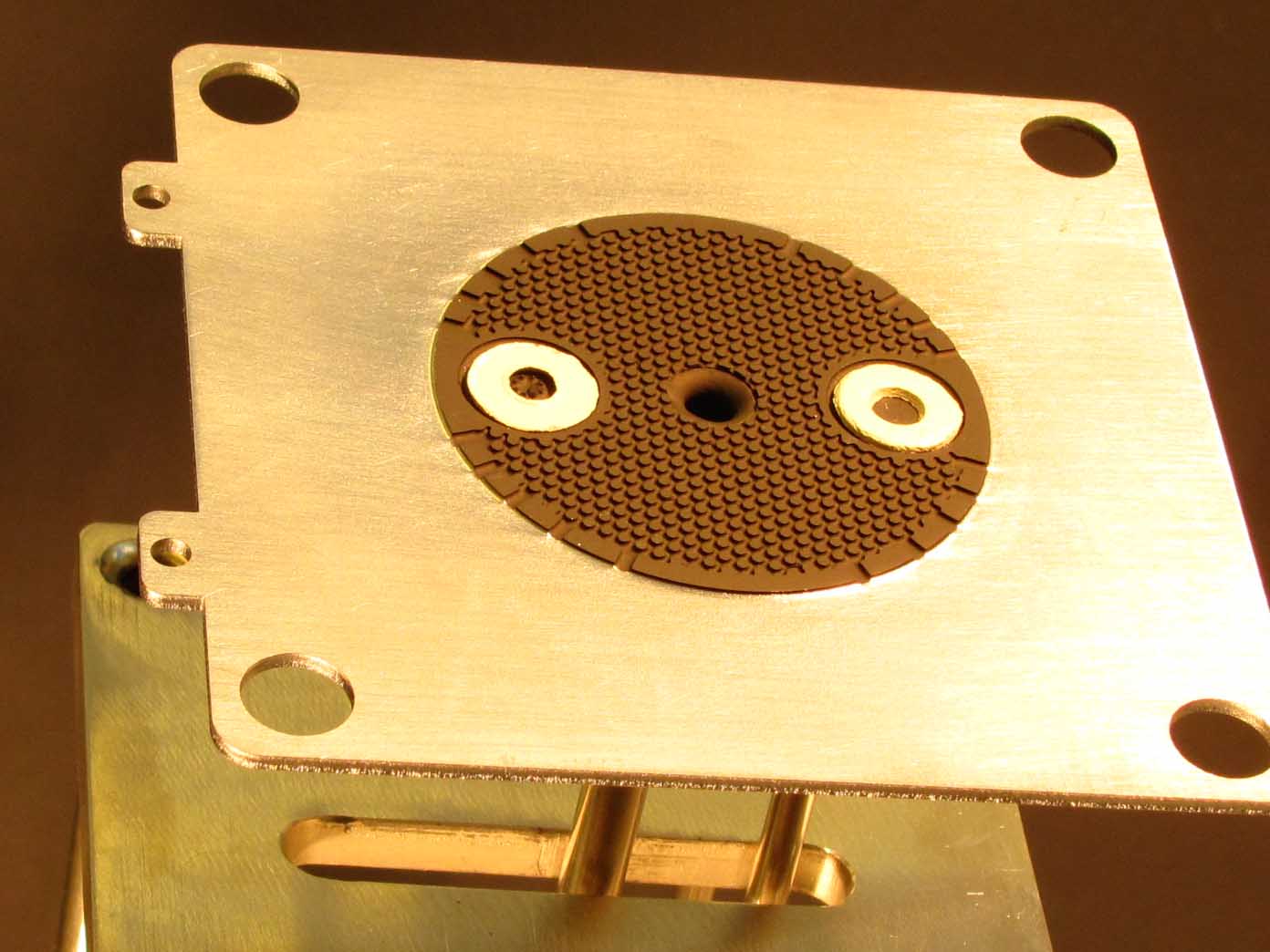

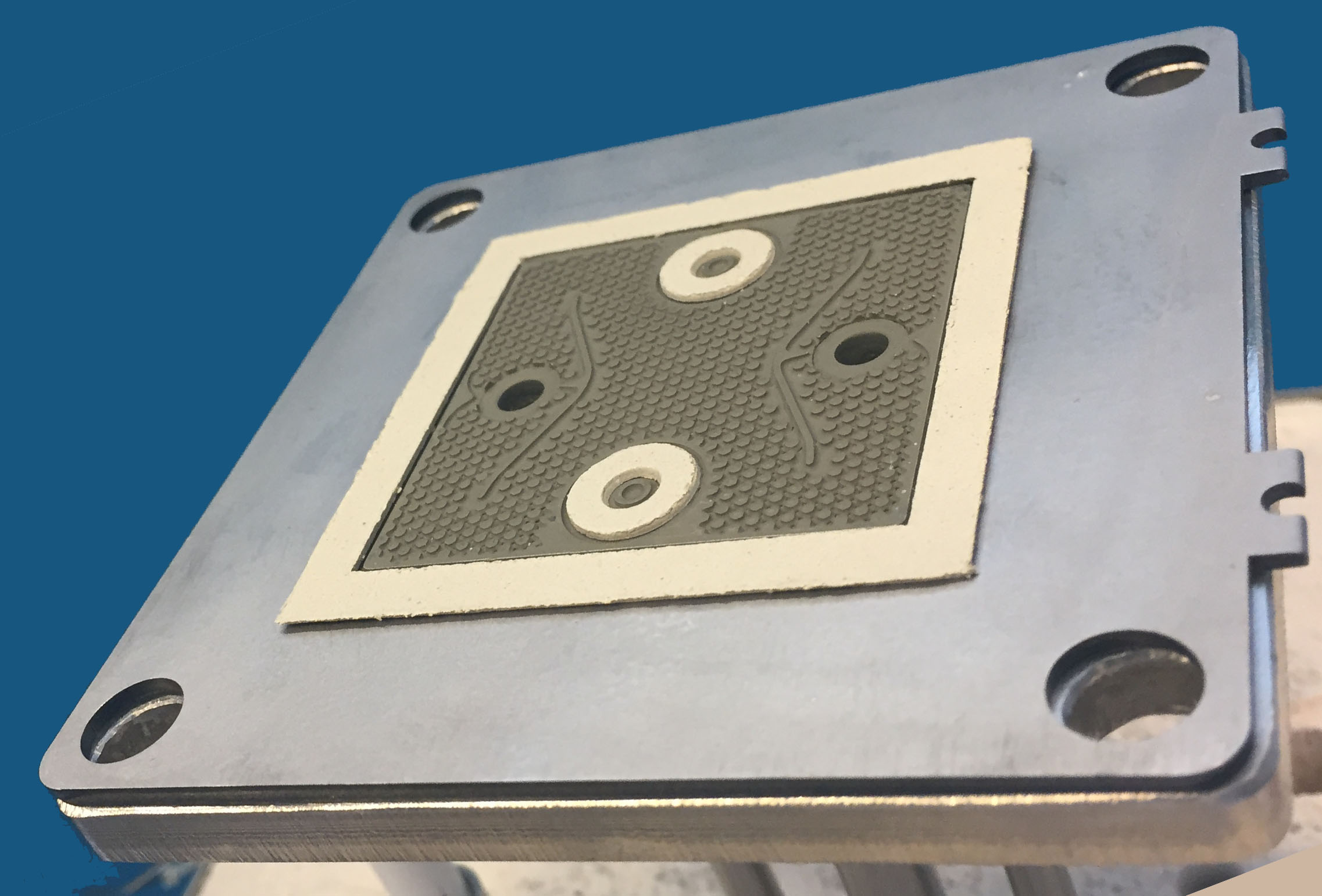

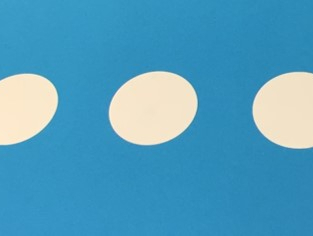

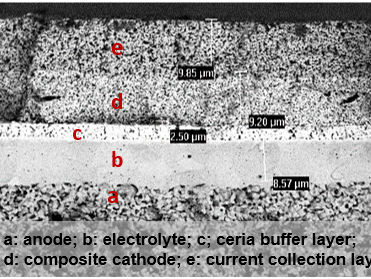

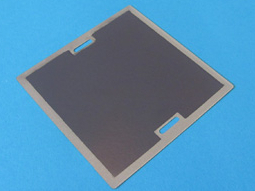

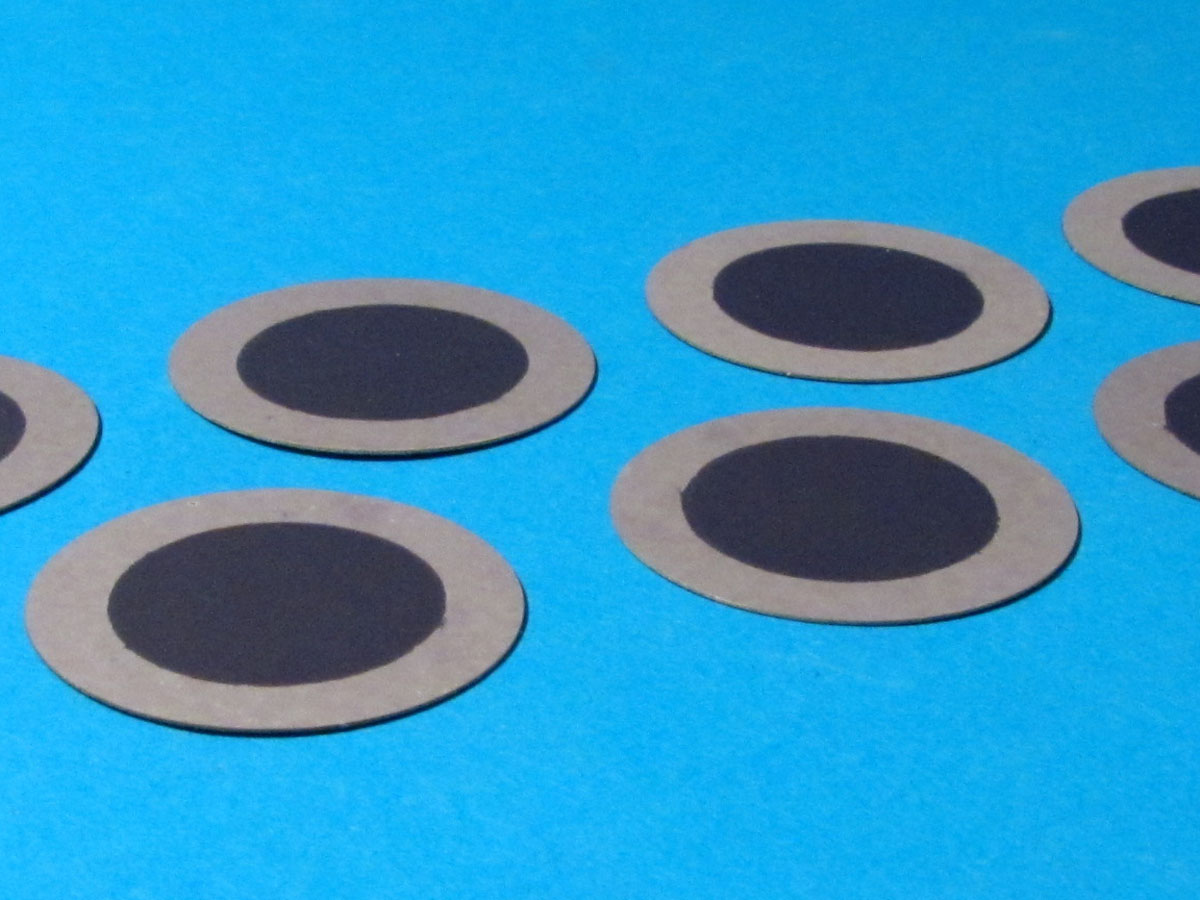

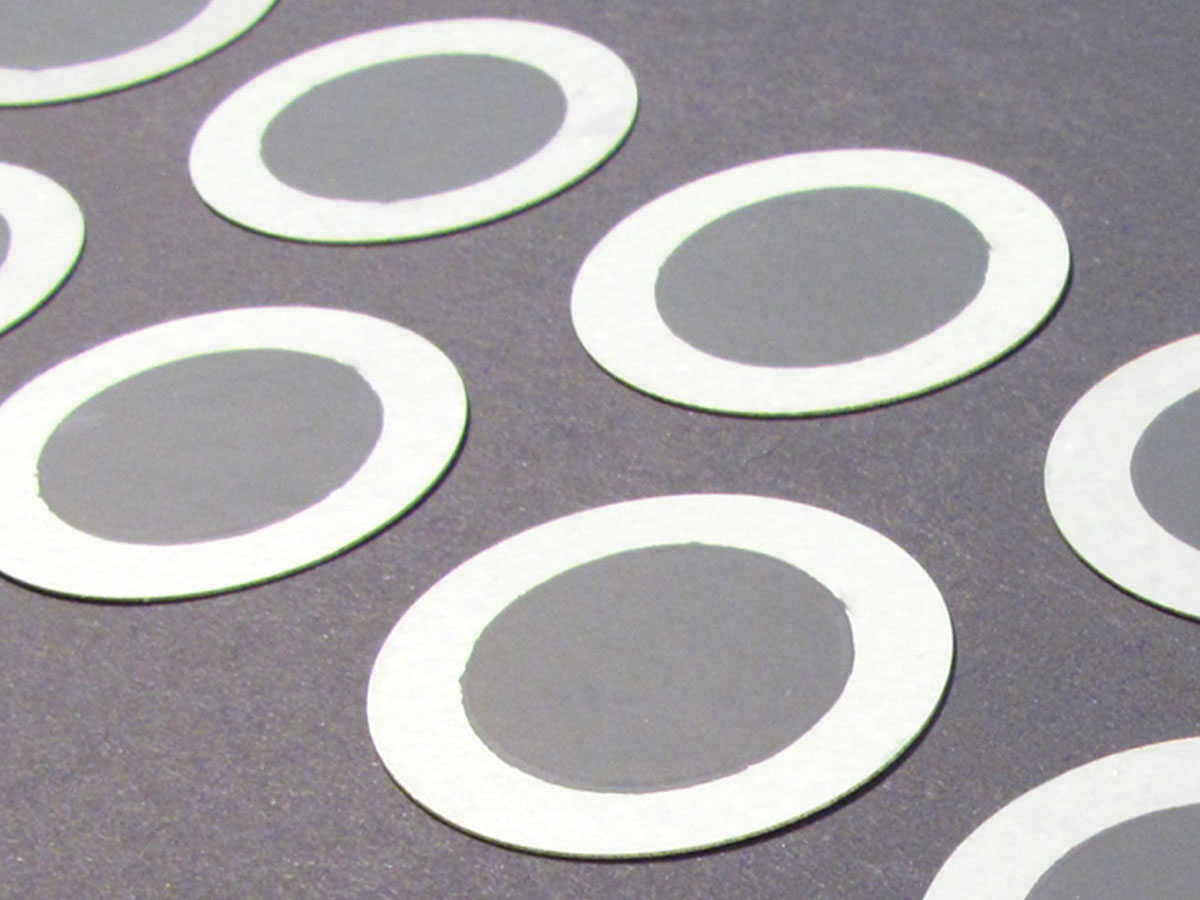

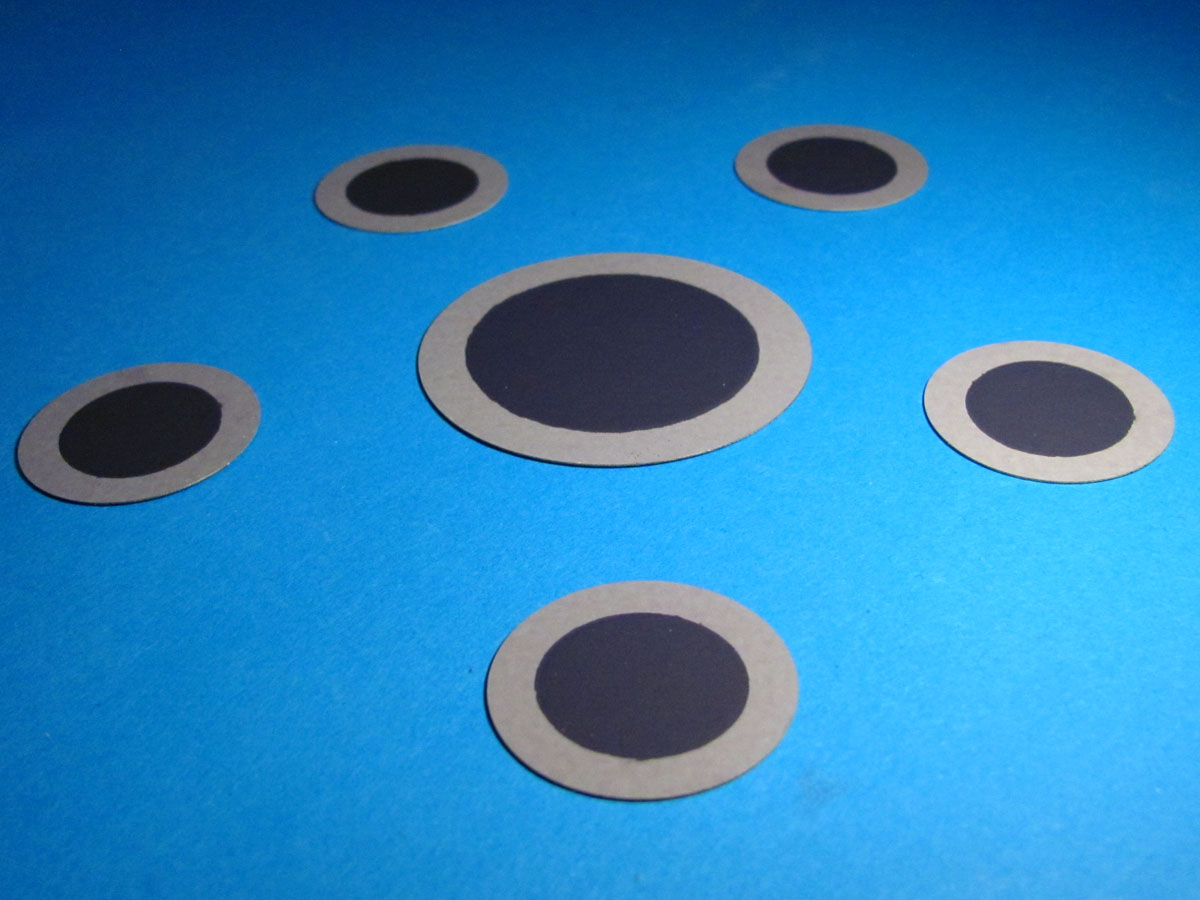

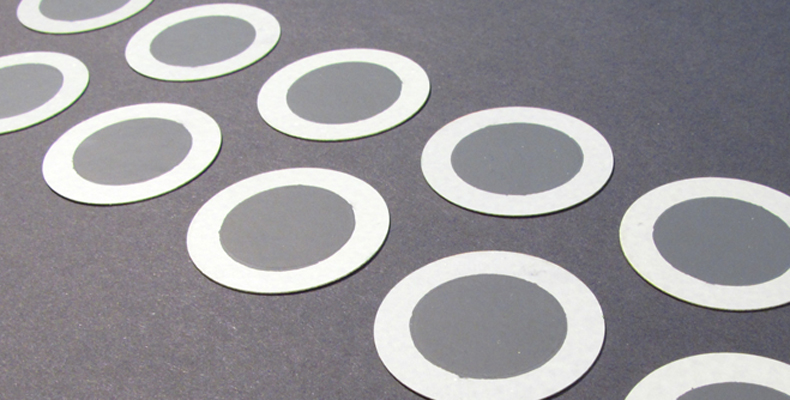

2R-Cell™ sintered at >1350 °C for few hours. The grey layer is the protective ceria barrier doped with cobalt At the end of the process, solid and flat cells are obtained. The picture (right) shows a batch of 2R-Cell™ sintered at >1350 °C for few hours followed by laser cutting at 30 mm of diameter.

2R-Cell™ sintered at >1350 °C for few hours. The grey layer is the protective ceria barrier doped with cobalt At the end of the process, solid and flat cells are obtained. The picture (right) shows a batch of 2R-Cell™ sintered at >1350 °C for few hours followed by laser cutting at 30 mm of diameter.

The grey layer is the protective ceria barrier on 8YSZ thin electrolyte that has been post-sintered at T<1200°C. This color comes from the cobalt used to dope the ceria in order to decrease the sintering temperature.

The cathode, a LSCF/GDC composite with a LSCF current collection layer, has been sintered at 1000°C during two hours.

Recommended literature:

Tape Casting: Theory and Practice by Richard E. Mistler and Eric R. TwinameDownload the brochure:

Click on the picture to download the brochure or click here to go to all Fiaxell brochures